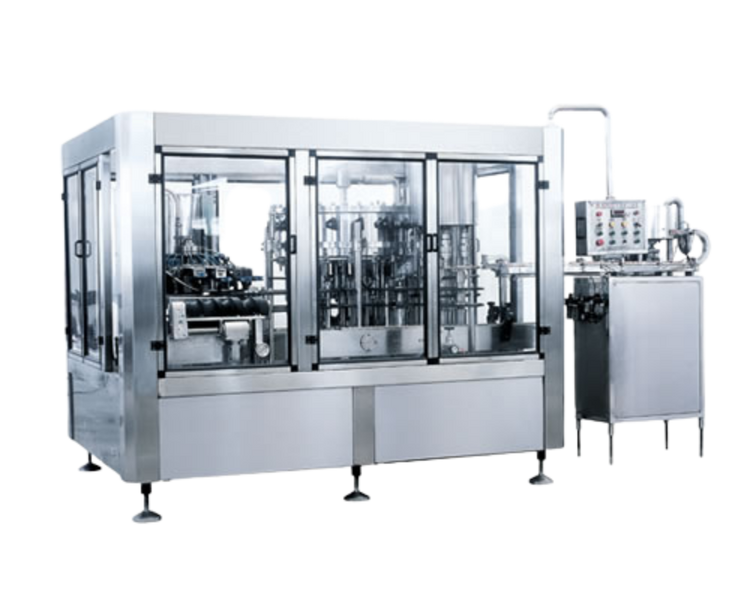

Automatic Complete Carbonated Soft Drink filling machine

Features of Automatic Complete carbonated filling machine

Design: Vertical Cylindrical tank with Center Low RPM Stirrer .

The tank shell will be of 2.mm thick S.S. sheets of SS304-

The tank bottom conical will be of 2.5.mm thick S.S. sheets of SS304

The tanks will be supported on S.S three legs provided with S.S. adjustable heavy duty ball feet for level adjustment, the bottom of the tank is conical type and also connected towards outlet for free and complete drainage of Juice.

All SS surfaces will matt polished to 220 grit, ground & smooth.

The Tank will be provided with following accessories

Top cover with two side openable lead Inlet connection with T.C. Connection for Pulp. (1no.)

Inlet connection with T.C. Flavor/Sugar syrup Water. (1no.)

Detail Specification

Sugar syrup preparation tank with low RPM stirrer (2 H.P)

Capacity – 1000Ltr

Function Requirement: Sugar Syrup Preparation tank is used for dissolving sugar in hot water to prepare sugar syrup.

Design: Vertical Cylindrical tank with Center Low RPM Stirrer .

The tank inner shell will be of 2 mm thick S.S. sheets of SS304.

The outer shell will be insulated with 100 mm thick 30 kg/mtr density glass wool/Cerawool and covered with 1.6 mm thick welded SS304 sheets.

The tanks will be supported on S.S three legs provided with S.S. adjustable heavy duty ball feet for level adjustment, the bottom of the tank is conical type type and also connected with Flush Bottom Valve to towards outlet for free and complete drainage of sugar syrup.

Electrically heated with temperature controlling system.

All SS surfaces will matt polished to 220 grit, ground & smooth.

The Tank will be provided with following

Sugar syrup filter press with transfer

pump It has facility to removing initial air from inside through air release valve.

Pressure gauge is provided to check filter chocking level(Pressure)

The stainless steel filter presses body is made to a special modular design that guarantees precisely the right filtration requirement for this application.

Easy open able body it is made out of SS304 quality sheet and provided with specially designed plate & safety valve.

Can use multi use washable filter cloth or use

n through grade filter cloth.

Vertical “Zero hold up design “ to use last drop of sugar syrup ( Crompton/equivalent

make)

40 BPM soft drink plant

Fully Automatic CSD Rinsing, Filling, Capping Machine 9-9-4 Rotary Based

(Cold Filling process)—-Filling Pressure will be 2 to 4 deg. Temperature.

8 Head Rising, 8 Head Counter pressure Filling and 4 Head Screw capping machine with cap Feeder, VFD etc.

- In feed Air Conveyor

- Exit Conveyor

Theoretical Output :- up to 40 BPM

INFEED AIR CONVEYOR

The empty bottles are loaded manually onto the in feed air conveyor where air at high pressure from a blower is used for conveying bottles supported at the neck upto the infeed bottle transfer rotor. The air conveyor permits different bottle sizes to run without making any adjustments. Hence there is no wastage of time in conveyor adjustment on the in feed side.

INFEED BOTTLE TRANSFER ROTOR

The bottles are transferred to rinse rotor by the in feed bottle transfer rotor. Bottles are held at the neck during transfer.

The automatic rinse rotor has spring loaded grippers mounted radially which pick up bottles one by one from the infeed transfer rotor. The bottle is inverted against a lever on the rinse valve to start the rinsing operation. Thus we have NO BOTTLE – NO RINSE. Bottles are washed for upto three seconds each, before draining (for removal of residual water) and up righting for transfer to the filling rotor. The rinsing medium is generally product water.

FILLING ROTOR

The internationally accepted and approved VENT PIPE filling principle ensures accurate level filling without spillage. The filling accuracy is +- 5ml. The fill tank level is regulated automatically by a PLC controlled electronic probe which reduces the machine speed in the vent of disrupted input product water supply. The machine speed is them restored to normal once the water supply is replenished.

Technical Specification

Online Disc Filter |

C.I.P pipe line For soft drink S.S 304 25mm C.I.P line Parallelly use same pump and ss304 tank used for C.I.P. S.S 304 C.I.P spray ball used in tank |

Interconnecting S.S. Pipes and Fittings — SS 304 for soft drink S.S. Pipes and Fittings for the equipment. The piping will be 25 mm as applicable based on the flow rate requirements. The fittings will be of TC end standard. |

MULTI STAGE Carbonator – 1000Ltr (Standard) with high pressure pump for carbonation (Lubi Make) Stainless steel high quality carbonated soft drink carbonation mixer, multi layer S.S plate for more precise carbonation with stainless steel vertical high pressure pump, insulted vessel, zero hold up design, C02 regulation system, high pressure auto and manual safety valve provided |

Standard Quality Glycol based chiller with Compressor ( Copland and safety denfoss make) 304 glycol insulated tank |

Pre carbonation PHE with Glycol circulation pump and automation with carbonator |

CO2Mani fold – Carbon dioxide multi cylinder connector with CO2 pressure gage and pressure regulator with header |

Application / Uses

Automatic Carbonated soft Drink Packaging line with water bottling machine.

Product Video

Packing Designs

Size Variations

Soft Drink 200ml 300ml 500ml 1Liter 1.5 Liter 2Liter

Delivery Countries

| Afghanistan | Dominican Republic | Lesotho | Saint Lucia |

| Albania | East Timor (Timor-Leste) | Liberia | Saint Vincent and the Grenadines |

| Algeria | Ecuador | Libya | Samoa |

| Andorra | Egypt | Liechtenstein | San Marino |

| Angola | El Salvador | Lithuania | Sao Tome and Principe |

| Antigua and Barbuda | Equatorial Guinea | Luxembourg | Saudi Arabia |

| Argentina | Eritrea | Madagascar | Senegal |

| Armenia | Estonia | Malawi | Serbia |

| Australia | Eswatini | Malaysia | Seychelles |

| Austria | Ethiopia | Maldives | Sierra Leone |

| Azerbaijan | Fiji | Mali | Singapore |

| The Bahamas | Finland | Malta | Slovakia |

| Bahrain | France | Marshall Islands | Slovenia |

| Bangladesh | Gabon | Mauritania | Solomon Islands |

| Barbados | The Gambia | Mauritius | Somalia |

| Belarus | Georgia | Mexico | South Africa |

| Belgium | Germany | Micronesia, Federated States of | Spain |

| Belize | Ghana | Moldova | Sri Lanka |

| Benin | Greece | Monaco | Sudan |

| Bhutan | Grenada | Mongolia | Sudan, South |

| Bolivia | Guatemala | Montenegro | Suriname |

| Bosnia and Herzegovina | Guinea | Morocco | Sweden |

| Botswana | Guinea-Bissau | Mozambique | Switzerland |

| Brazil | Guyana | Myanmar (Burma) | Syria |

| Brunei | Haiti | Namibia | Taiwan |

| Bulgaria | Honduras | Nauru | Tajikistan |

| Burkina Faso | Hungary | Nepal | Tanzania |

| Burundi | Iceland | Netherlands | Thailand |

| Cabo Verde | India | New Zealand | Togo |

| Cambodia | Indonesia | Nicaragua | Tonga |

| Cameroon | Iran | Niger | Trinidad and Tobago |

| Canada | Iraq | Nigeria | Tunisia |

| Central African Republic | Ireland | North Macedonia | Turkey |

| Chad | Israel | Norway | Turkmenistan |

| Chile | Italy | Oman | Tuvalu |

| China | Jamaica | Pakistan | Uganda |

| Colombia | Japan | Palau | Ukraine |

| Comoros | Jordan | Panama | United Arab Emirates |

| Congo, Democratic Republic of the | Kazakhstan | Papua New Guinea | United Kingdom |

| Congo, Republic of the | Kenya | Paraguay | United States |

| Costa Rica | Kiribati | Peru | Uruguay |

| Côte d’Ivoire | Korea, North | Philippines | Uzbekistan |

| Croatia | Korea, South | Poland | Vanuatu |

| Cuba | Kosovo | Portugal | Vatican City |

| Cyprus | Kuwait | Qatar | Venezuela |

| Czech Republic | Kyrgyzstan | Romania | Vietnam |

| Denmark | Laos | Russia | Yemen |

| Djibouti | Latvia | Rwanda | Zambia |

| Dominica | Lebanon | Saint Kitts and Nevis | Zimbabwe |

Delivery Time

We will take Max 1 month to deliver your product at your office.