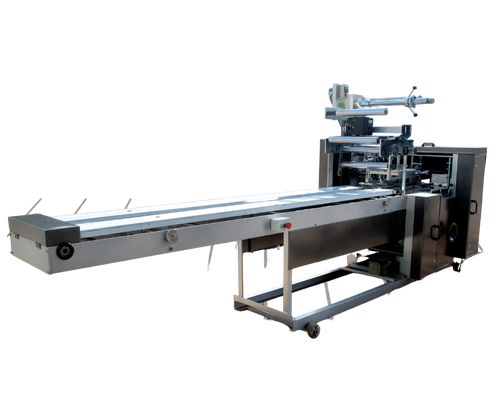

New Automatic Bopp Film Packaging Machine

Features of New Automatic Bopp Film Packaging Machine

Model | Astra-42 Owrm |

Product | cartons ( 10 x 2 Matrix) |

Purpose of the Machine | Bundling of the Masala Pharma Milk Powder Cosmetic Herbal Corn Flak Cartons with the BOPP Film. |

Detail Specification

· The Cartons coming from the Cartoning machine will be taken by the input conveyor of the Bundling and Over Wrapping machine. · A rotating orientor will change the orientation of the cartons to 90 degrees and feed it further on the conveyor. · A pack pusher will separate the required no of cartons (10 no.) and takes it in front of the main pusher. · The main pusher will push the pack to the wrapping station. · The film roll mounted on the machine will be drawn and cut to the required length. · The packs while being transferred to the wrapping station will take the film along with it. · The flaps will be folded and sealed with the help of the folder and sealing head. · The sides of the film wrapped onto pack will be folded simultaneously with the help of the folders mounted on the sides. · The folded ends will be sealed with the pair of heater body mounted on both the sides. |

Technical Specification

Power Supply | 2.2KW 3-phase 440V AC 50Hz |

Main Motor | 0.75kW(1 H.P) Bonfigloli or any other reputed make |

Gear Drive (Transmission) | Bonfiglolie make |

Servo motor | For Film draw 750 W, Mitsubishi make (make may Change depending on the availability at the time of manufacturing of the machine and the design requirements) |

Air Supply Input | 5 kg /cm2 (up to 10 CFM) Dry Compressed Air Note: compressor not part of supply and will have to be installed separately at your end. Alternatively Air-line can be tapped from your existing compressed air line ( final required will be submitted upon the final trials of the machine |

Sealing type | Direct Heat Sealing for Long seal as well as end Seals (envelope type folded seal) (optional dot type head sealing specially for Cartons) |

Conveyor | Belt: Endless type made of Shilon-25. Drive to the conveyor: direct thorough the main drive or through separate geared motor Dimensions: 2 Mt. Long, 6” wide, 1/8 “Thick. (Dimensions subject to change according to carton size and during actual manufacturing of the machine) |

Electrical Control Panel | Overall finish: S.S202 The panel will be provided for controls of all Electricals as well as Pneumatic circuit. Logic will be providing with No Cartoon M/C stop. Separate remote will be provided to ease of operations. Handling easily to the operator. |

AUTOMATIC CARTON BUNDLING & OVERWRAPPING MACHINE WITH SERVO

Astra-42- Owrm

Heating controls | Temperature Controllers Make – Selec for End Seal as well as Side seal operation. Heater & Probe: 1KW overall Make – Heatrej / Intergrity Heaters -dia.3/8” with 230V & 200W Probe – FEK Washer type

|

Sensors | Proximity sensor dia. 12mm OR 18mm PNP NO type 10-30V DC Make – Contronix (as per requirement of Application)

|

Pneumatics | Side Seal Cylinder – Festo Make Solenoid Valve – – Festo Make Fittings & Air Tube – – Festo Make FRL Unit – – Festo Make

|

Speed Controls | Speed controlled through the variable speed drive Mitsubishi make

|

Safety Interlocks | NO Carton on conveyor, machine stops Low air pressure machine off, Low Temperature machine off, Emergency on machine off.

|

Machine Structure | The frame will be MS Pipe ( 50×50 size, 3mm thick ) with Epoxy coating finishing |

Guards | S.S Pipe with Acrylic doors the doors will be fitted with magnetic locks. |

Machine Speed /Output per min | The machine is designed for an average speed of up to 10 Packs per min. however this speed will depend on the Cartons dimensions, weight of the filled cartons as well as the type of the cartons |

Machine weight | Approximate 1200kgs |

Application / Uses

Automatic Pouch Cartoning line For Milk Carton Pharmaceutical Carton Celphone Carton

Product Video

Packing Designs

Size Variations

pusher will push the pack to the wrapping station

Delivery Countries

| Afghanistan | Dominican Republic | Lesotho | Saint Lucia |

| Albania | East Timor (Timor-Leste) | Liberia | Saint Vincent and the Grenadines |

| Algeria | Ecuador | Libya | Samoa |

| Andorra | Egypt | Liechtenstein | San Marino |

| Angola | El Salvador | Lithuania | Sao Tome and Principe |

| Antigua and Barbuda | Equatorial Guinea | Luxembourg | Saudi Arabia |

| Argentina | Eritrea | Madagascar | Senegal |

| Armenia | Estonia | Malawi | Serbia |

| Australia | Eswatini | Malaysia | Seychelles |

| Austria | Ethiopia | Maldives | Sierra Leone |

| Azerbaijan | Fiji | Mali | Singapore |

| The Bahamas | Finland | Malta | Slovakia |

| Bahrain | France | Marshall Islands | Slovenia |

| Bangladesh | Gabon | Mauritania | Solomon Islands |

| Barbados | The Gambia | Mauritius | Somalia |

| Belarus | Georgia | Mexico | South Africa |

| Belgium | Germany | Micronesia, Federated States of | Spain |

| Belize | Ghana | Moldova | Sri Lanka |

| Benin | Greece | Monaco | Sudan |

| Bhutan | Grenada | Mongolia | Sudan, South |

| Bolivia | Guatemala | Montenegro | Suriname |

| Bosnia and Herzegovina | Guinea | Morocco | Sweden |

| Botswana | Guinea-Bissau | Mozambique | Switzerland |

| Brazil | Guyana | Myanmar (Burma) | Syria |

| Brunei | Haiti | Namibia | Taiwan |

| Bulgaria | Honduras | Nauru | Tajikistan |

| Burkina Faso | Hungary | Nepal | Tanzania |

| Burundi | Iceland | Netherlands | Thailand |

| Cabo Verde | India | New Zealand | Togo |

| Cambodia | Indonesia | Nicaragua | Tonga |

| Cameroon | Iran | Niger | Trinidad and Tobago |

| Canada | Iraq | Nigeria | Tunisia |

| Central African Republic | Ireland | North Macedonia | Turkey |

| Chad | Israel | Norway | Turkmenistan |

| Chile | Italy | Oman | Tuvalu |

| China | Jamaica | Pakistan | Uganda |

| Colombia | Japan | Palau | Ukraine |

| Comoros | Jordan | Panama | United Arab Emirates |

| Congo, Democratic Republic of the | Kazakhstan | Papua New Guinea | United Kingdom |

| Congo, Republic of the | Kenya | Paraguay | United States |

| Costa Rica | Kiribati | Peru | Uruguay |

| Côte d’Ivoire | Korea, North | Philippines | Uzbekistan |

| Croatia | Korea, South | Poland | Vanuatu |

| Cuba | Kosovo | Portugal | Vatican City |

| Cyprus | Kuwait | Qatar | Venezuela |

| Czech Republic | Kyrgyzstan | Romania | Vietnam |

| Denmark | Laos | Russia | Yemen |

| Djibouti | Latvia | Rwanda | Zambia |

| Dominica | Lebanon | Saint Kitts and Nevis | Zimbabwe |

Delivery Time

We will take Max 1 month to deliver your product at your office.