Automatic shrink wrapping machine in Uganda price

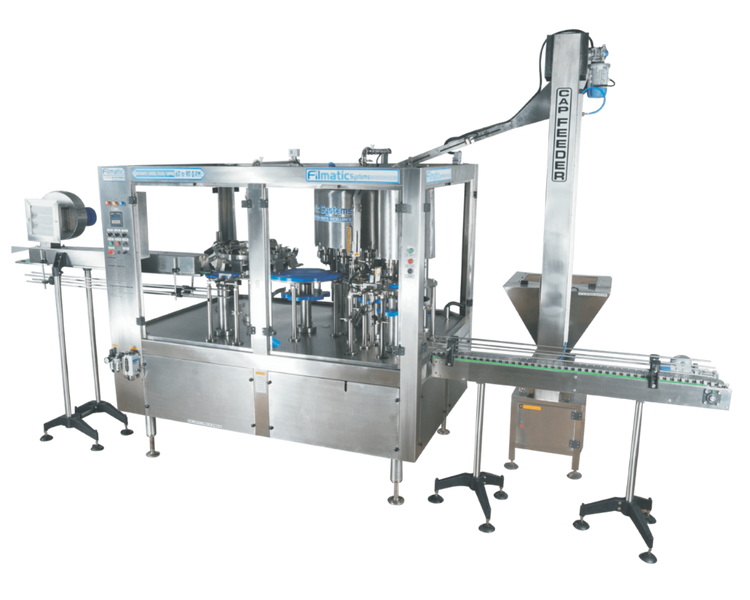

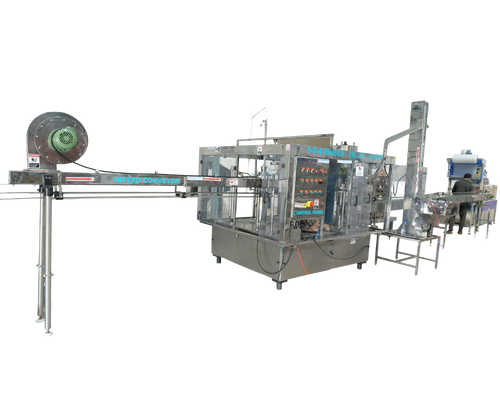

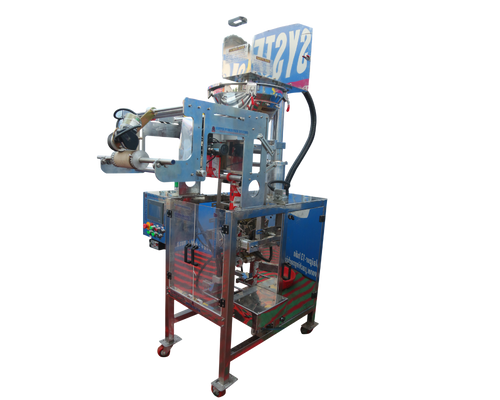

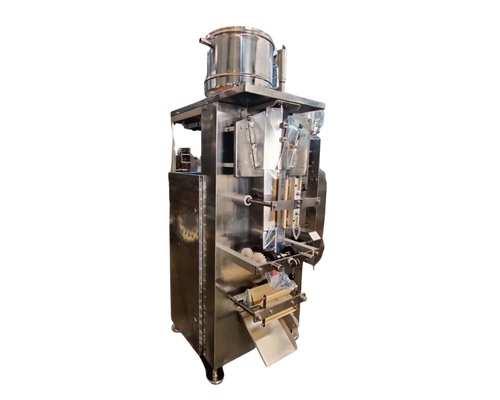

Automatic Shrink Wrapping Machine for Group 12 Bottle 24 Bottle Mineral Water Soft Drink Juice Oil Milk Pet Bottles in Kampala Uganda

Detail Specification

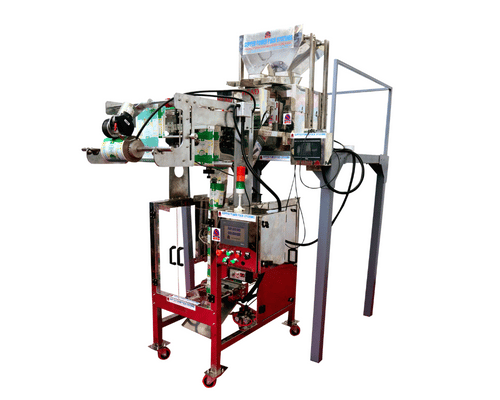

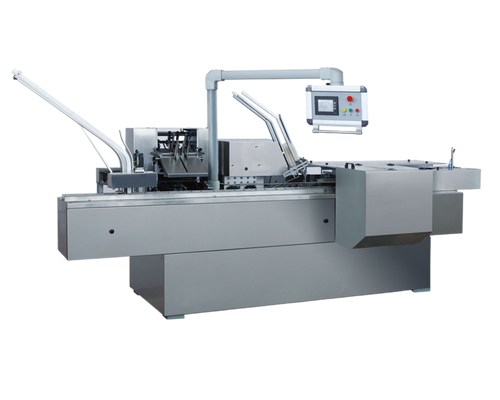

· The Cartons coming from the Cartoning machine will be taken by the input conveyor of the Bundling and Over Wrapping machine.

· A rotating orientor will change the orientation of the cartons to 90 degrees and feed it further on the conveyor.

· A pack pusher will separate the required no of cartons (10 no.) and takes it in front of the main pusher.

· The main pusher will push the pack to the wrapping station.

· The film roll mounted on the machine will be drawn and cut to the required length.

· The packs while being transferred to the wrapping station will take the film along with it.

· The flaps will be folded and sealed with the help of the folder and sealing head.

· The sides of the film wrapped onto pack will be folded simultaneously with the help of the folders mounted on the sides.

· The folded ends will be sealed with the pair of heater body mounted on both the sides.

Technical Specification

Power Supply

2.2KW 3-phase 440V AC 50Hz

Main Motor

0.75kW(1 H.P) Bonfigloli or any other reputed make

Gear Drive (Transmission)

Bonfiglolie make

Servo motor

For Film draw

750 W, Mitsubishi make (make may Change depending on the availability at the time of manufacturing of the machine and the design requirements)

Air Supply Input

5 kg /cm2 (up to 10 CFM) Dry Compressed Air

Note: compressor not part of supply and will have to be installed separately at your end. Alternatively Air-line can be tapped from your existing compressed air line ( final required will be submitted upon the final trials of the machine

Sealing type

Direct Heat Sealing for Long seal as well as end Seals (envelope type folded seal)

(optional dot type head sealing specially for Cartons)

Conveyor

Belt: Endless type made of Shilon-25.

Drive to the conveyor: direct thorough the main drive or through separate geared motor

Dimensions: 2 Mt. Long, 6” wide, 1/8 “Thick.

(Dimensions subject to change according to carton size and during actual manufacturing of the machine)

Electrical Control Panel

Overall finish: S.S202

The panel will be provided for controls of all Electricals as well as Pneumatic circuit.

Logic will be providing with No Cartoon M/C stop.

Separate remote will be provided to ease of operations. Handling easily to the operator.

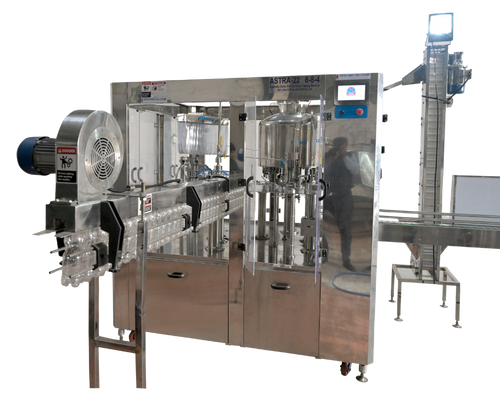

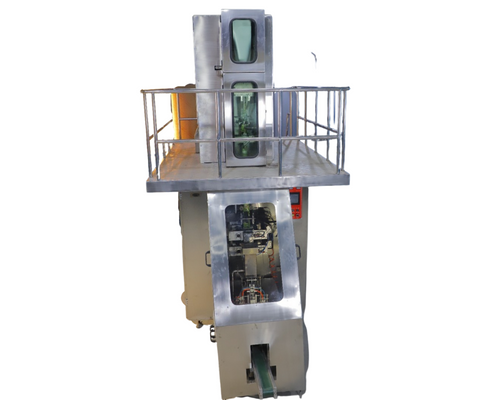

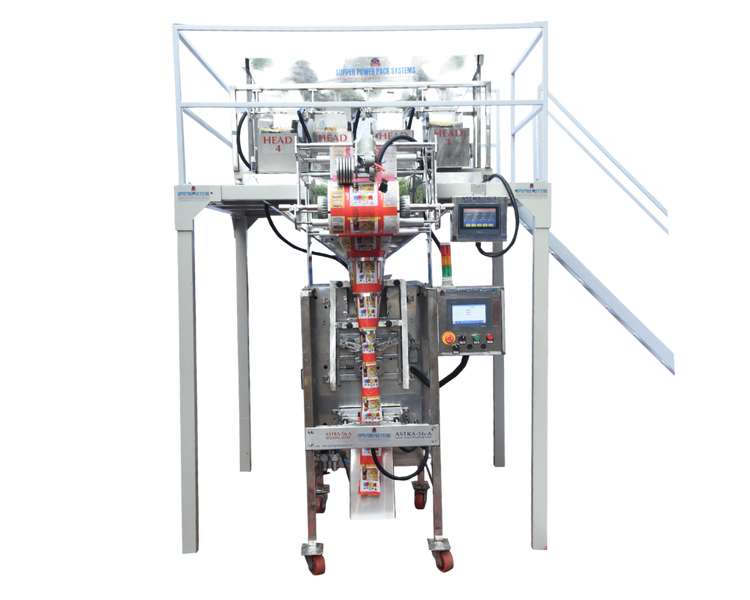

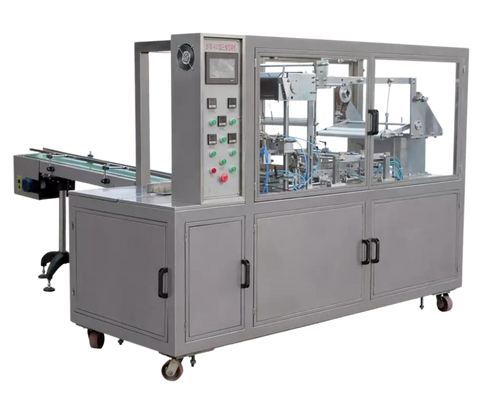

AUTOMATIC CARTON BUNDLING & OVERWRAPPING MACHINE WITH SERVO

Astra-42- Owrm

Heating controls

Temperature Controllers Make – Selec for End Seal as well as Side seal operation.

Heater & Probe: 1KW overall Make – Heatrej / Intergrity Heaters -dia.3/8” with 230V & 200W

Probe – FEK Washer type

Sensors

Proximity sensor dia. 12mm OR 18mm PNP NO type 10-30V DC Make – Contronix (as per requirement of Application)

Pneumatics

Side Seal Cylinder – Festo Make

Solenoid Valve – – Festo Make

Fittings & Air Tube – – Festo Make

FRL Unit – – Festo Make

Speed Controls

Speed controlled through the variable speed drive Mitsubishi make

Safety Interlocks

NO Carton on conveyor, machine stops

Low air pressure machine off,

Low Temperature machine off,

Emergency on machine off.

Machine Structure

The frame will be MS Pipe ( 50×50 size, 3mm thick ) with Epoxy coating finishing

Guards

S.S Pipe with Acrylic doors the doors will be fitted with magnetic locks.

Machine Speed /Output per min

The machine is designed for an average speed of up to 10 Packs per min. however this speed will depend on the Cartons dimensions, weight of the filled cartons as well as the type of the cartons

Machine weight

Approximate 1200kgs

Application / Uses

Masala cartons ( 10 x 2 Matrix)

What we do?

We Manufacture , Export , Supply , Trade , Import shrink wrapping machine in Uganda

Call us or fill the form for more information.

What we do ? we shrink wrapping machine in Uganda and supply

Why Uganda for shrink wrapping machine ?

Automatic Shrink Wrapping Machine for Group 12 Bottle 24 Bottle Mineral Water Soft Drink Juice Oil Milk Pet Bottles in Kampala Uganda

Uganda is a landlocked country in East Africa whose diverse landscape encompasses the snow-capped Rwenzori Mountains and immense Lake Victoria. Its abundant wildlife includes chimpanzees as well as rare birds. Remote Bwindi Impenetrable National Park is a renowned mountain gorilla sanctuary. Murchison Falls National Park in the northwest is known for its 43m-tall waterfall and wildlife such as hippos. ? Google

Introduction

In the bustling city of Kampala, Uganda, the demand for efficient and reliable packaging solutions is on the rise. Businesses across various sectors, from beverage to dairy, are seeking advanced machinery to streamline their operations and ensure their products reach consumers in pristine condition. Among the most essential equipment in this regard is the Automatic Shrink Wrapping Machine. Designed to handle a range of packaging needs, this machine is particularly suited for grouping 12 to 24 bottles of mineral water, soft drinks, juice, oil, milk, and PET bottles. In this comprehensive guide, we will delve into the features, benefits, and applications of the Automatic Shrink Wrapping Machine, highlighting why it is the preferred choice for businesses in Kampala and beyond.

The Need for Efficient Packaging Solutions

In the modern marketplace, efficient packaging is crucial for several reasons. Firstly, it protects products during transportation and storage, ensuring they reach consumers without damage. Secondly, it enhances the visual appeal of products, making them more attractive to potential buyers. Thirdly, efficient packaging solutions can significantly reduce operational costs by minimizing waste and improving productivity.

In Kampala, where the market for bottled beverages and other liquid products is expanding rapidly, businesses need to invest in machinery that can keep up with the high demand. The Automatic Shrink Wrapping Machine is one such investment that promises to revolutionize packaging processes.

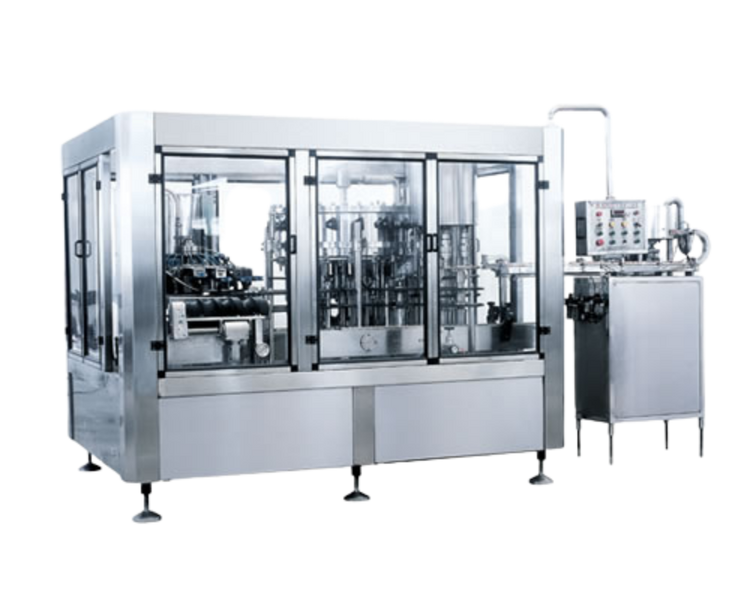

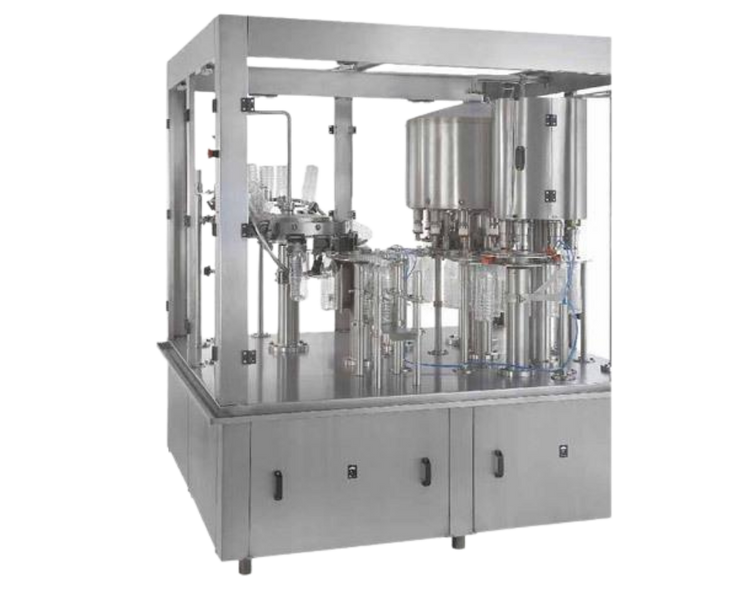

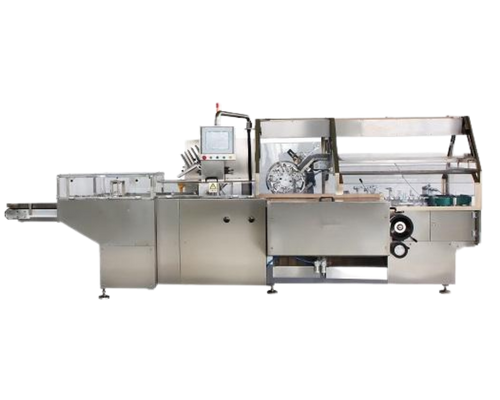

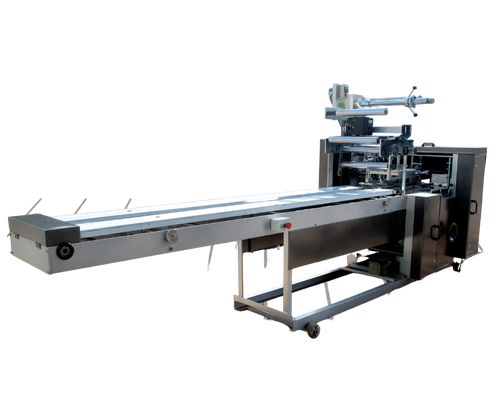

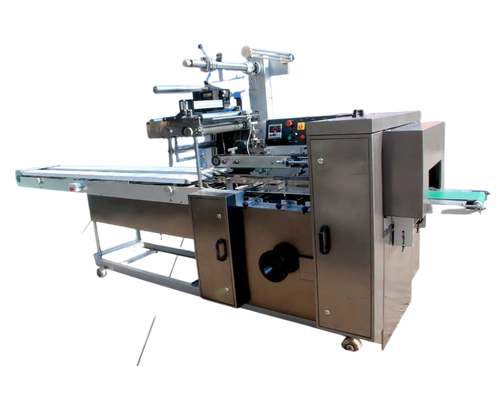

What is an Automatic Shrink Wrapping Machine?

An Automatic Shrink Wrapping Machine is a piece of equipment designed to wrap products using a shrinkable plastic film. The machine applies heat to the film, causing it to shrink tightly around the product. This process not only secures the items but also provides a professional and clean appearance.

These machines come in various models and configurations, each tailored to specific packaging needs. The model designed for grouping 12 to 24 bottles is particularly popular in the beverage and dairy industries. It can handle different types of bottles, including those made from PET (polyethylene terephthalate), a common material for beverage containers.

Key Features of the Automatic Shrink Wrapping Machine

1. High Throughput

One of the standout features of the Automatic Shrink Wrapping Machine is its high throughput. It can process a large number of bottles per minute, making it ideal for businesses with high production volumes. This efficiency ensures that companies can meet market demands without delays.

2. Versatility

The machine is designed to handle a variety of bottle sizes and types, including mineral water, soft drinks, juice, oil, and milk bottles. This versatility is particularly beneficial for businesses that produce multiple types of beverages or liquids. It eliminates the need for separate machines for different products, thereby saving space and reducing costs.

3. Precision and Consistency

Precision is crucial in packaging, and the Automatic Shrink Wrapping Machine excels in this area. It ensures that each package is wrapped tightly and uniformly, providing a professional appearance and reducing the risk of product damage during transportation. The consistent wrapping quality also enhances the brand image, making the products more appealing to consumers.

4. User-Friendly Interface

Modern Automatic Shrink Wrapping Machines are equipped with user-friendly interfaces, making them easy to operate. They come with programmable settings that allow operators to adjust the machine according to specific packaging requirements. This ease of use reduces the need for extensive training and allows for quick setup and changeovers.

5. Energy Efficiency

Energy efficiency is a key consideration for businesses looking to reduce operational costs and environmental impact. The Automatic Shrink Wrapping Machine is designed to use minimal energy while maintaining high performance. Advanced heating elements and insulation techniques ensure that heat is applied efficiently, reducing energy consumption.

6. Robust Construction

Durability is essential for any industrial machinery, and the Automatic Shrink Wrapping Machine is built to last. It features a robust construction with high-quality materials that can withstand the rigors of daily use. This durability translates to lower maintenance costs and a longer lifespan, providing excellent value for money.

Benefits of Using an Automatic Shrink Wrapping Machine

1. Improved Productivity

The primary benefit of using an Automatic Shrink Wrapping Machine is the significant boost in productivity. By automating the wrapping process, businesses can package more products in less time. This increased efficiency allows companies to meet high demand and expand their market reach.

2. Enhanced Product Protection

Shrink wrapping provides a secure and protective layer around products. It shields them from dust, moisture, and other contaminants, ensuring that they remain in excellent condition until they reach the consumer. This protection is especially important for beverages and dairy products, which need to maintain their quality and freshness.

3. Cost Savings

While the initial investment in an Automatic Shrink Wrapping Machine may be substantial, the long-term cost savings are significant. The machine reduces the need for manual labor, lowers packaging material waste, and minimizes the risk of product damage. These savings can quickly offset the initial purchase cost.

4. Professional Packaging

The uniform and tight wrapping provided by the machine gives products a professional appearance. This is crucial for brand image and consumer perception. Well-packaged products are more likely to attract buyers and convey a sense of quality and reliability.

5. Versatility and Flexibility

The ability to handle various bottle sizes and types makes the Automatic Shrink Wrapping Machine a versatile addition to any production line. Businesses can easily switch between different products without needing multiple machines. This flexibility is particularly beneficial for companies that produce seasonal or limited-edition products.

6. Environmental Benefits

Shrink wrapping can be more environmentally friendly compared to other packaging methods. The film used in shrink wrapping is often recyclable, and the process generates minimal waste. Additionally, the machine’s energy-efficient operation reduces the overall environmental impact.

Applications in Kampala, Uganda

In Kampala, the market for bottled beverages and other liquid products is thriving. The city’s growing population and increasing urbanization are driving demand for convenient and reliable packaging solutions. The Automatic Shrink Wrapping Machine is well-suited to meet these needs across various industries.

1. Beverage Industry

The beverage industry in Kampala is one of the primary beneficiaries of the Automatic Shrink Wrapping Machine. Producers of mineral water, soft drinks, and juices can use the machine to efficiently package their products in groups of 12 or 24 bottles. The secure and attractive packaging enhances the shelf appeal and ensures that the products remain in top condition during transportation and storage.

2. Dairy Industry

Dairy products, such as milk, require careful packaging to maintain their freshness and quality. The Automatic Shrink Wrapping Machine provides an ideal solution for grouping milk bottles. Its precise wrapping ensures that the bottles are securely packaged, reducing the risk of leakage and spoilage.

3. Edible Oil Industry

In the edible oil industry, packaging is crucial to prevent contamination and ensure product safety. The Automatic Shrink Wrapping Machine can efficiently package oil bottles, providing a protective barrier against external contaminants. This ensures that the oil reaches consumers in perfect condition.

4. Household and Personal Care Products

Beyond beverages and food products, the Automatic Shrink Wrapping Machine is also suitable for packaging household and personal care products. Bottles of cleaning solutions, shampoos, and lotions can be securely grouped and wrapped, making them easier to handle and transport.

5. Export Market

Kampala-based businesses looking to export their products can greatly benefit from the Automatic Shrink Wrapping Machine. The professional and secure packaging provided by the machine enhances the products’ appeal in international markets. It also ensures that the products reach their destination without damage, reducing the risk of returns and enhancing customer satisfaction.

Choosing the Right Automatic Shrink Wrapping Machine

When selecting an Automatic Shrink Wrapping Machine, businesses need to consider several factors to ensure they choose the right model for their needs.

1. Production Volume

The production volume is a critical factor in choosing the right machine. Businesses with high production volumes need a machine with a high throughput to meet their packaging needs efficiently.

2. Bottle Sizes and Types

Different machines are designed to handle specific bottle sizes and types. Businesses should choose a machine that can accommodate the variety of bottles they produce.

3. Space Availability

The available space in the production facility is another important consideration. Companies need to ensure that the machine fits within their space constraints without disrupting other operations.

4. Budget

While the initial investment in an Automatic Shrink Wrapping Machine can be substantial, businesses should consider the long-term cost savings and return on investment. It is important to choose a machine that offers the best value for money.

5. Technical Support and Maintenance

Reliable technical support and maintenance services are crucial for ensuring the machine operates smoothly. Businesses should choose a manufacturer that offers prompt and efficient customer support.

Conclusion

The Automatic Shrink Wrapping Machine is a game-changer for businesses in Kampala, Uganda, looking to enhance their packaging processes. Its high throughput, versatility, precision, and energy efficiency make it an ideal solution for packaging a variety of bottles, including mineral water, soft drinks, juice, oil, and milk. The machine offers numerous benefits, including improved productivity, enhanced product protection, cost savings, and professional packaging.

For businesses in Kampala, investing in an Automatic Shrink Wrapping Machine is a strategic move that can significantly boost their operational efficiency and market competitiveness. By choosing the right machine and leveraging its advanced features, companies can meet the growing demand for high-quality packaged products and expand their reach in both local and international markets.

With the Automatic Shrink Wrapping Machine, businesses in Kampala can take their packaging operations to the next level, ensuring their products stand out on the shelves and reach consumers in perfect condition.

Cities We Supply :

- Kampala

- Entebbe

- Jinja

- Mbarara

- Gulu

- Mbale

- Fort Portal

- Arua

- Lira

- Masaka