Rice: Rice Packing Machine, Rice Bag Packing Machine, Rice Packaging Equipment, Automatic Rice Packing Machine, Rice Bagging Machine, Rice Filling Machine, Rice Packaging Line.

Beans: Bean Packing Machine, Bean Bag Packing Machine, Bean Packaging Equipment, Automatic Bean Packing Machine, Bean Bagging Machine, Bean Filling Machine, Bean Packaging Line.

Sugar: Sugar Packing Machine, Sugar Bag Packing Machine, Sugar Packaging Equipment, Automatic Sugar Packing Machine, Sugar Bagging Machine, Sugar Filling Machine, Sugar Packaging Line.

50kg Bag: 50kg Bag Packing Machine, 50kg Bag Packaging Machine, 50kg Bag Filling Machine, 50kg Bag Sealing Machine, 50kg Bagging Equipment, Automatic 50kg Bag Packing Machine.

Packing Machine: Bag Packing Machine, Bagging Machine, Packaging Machine, Filling Machine, Sealing Machine, Automatic Packing Machine.

Zambia: Zambia Packaging Machine, Zambia Bagging Machine, Zambia Packing Equipment, Zambia Filling Machine, Zambia Bag Sealing Machine.

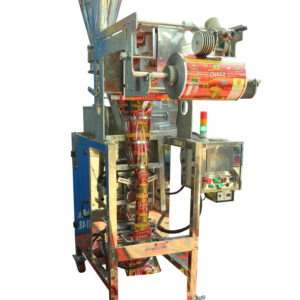

· Model: ASTRA-180

· Application: Bag Filling machine

· Material: Powder, Contact part SS304

· Type: Gross Weighed, Bagging System

· Weighing Capacity:10-50 kg

· Speed: 3-4 Bags/Minute(240

Bags/Hour)

· Accuracy: 0.7% FSD

· Load Cell Based Weighing System

· IP65 Control Panel with

Siemens Accessories

5kg 10kg 50kg Automatic Rice Bag Packing in Zambia

In Zambia’s agricultural sector, staple foods such as rice, beans and sugar are commonly consumed by the population. With increasing demand for these products, efficient and accurate packaging methods have become increasingly important to farmers, distributors and consumers. To meet these requirements, the introduction of advanced 50kg bag packing machines has brought about a revolution in the packaging process, thereby improving productivity, reducing labor costs and increasing product quality. This article explores the impact of these machines on the rice, beans and sugar industry in Zambia.

Automation and Efficiency:

Traditionally, the packaging of rice, beans and sugar in 50 kg bags was a laborious and time-consuming process. However, with the advent of automated packing machines, the process has become highly efficient. These machines are capable of handling large volumes of products, reducing manual labor and increasing overall productivity. They can accurately measure the desired weight of each bag, ensuring consistent packaging standards and minimizing product waste.

Enhanced accuracy and quality:

Manual packing methods were prone to human errors, which led to discrepancies in bag weight and overall product quality. The introduction of advanced packing machines in Zambia has overcome these challenges by providing accurate measurements and uniform packing. The machines are equipped with sensors and controls that ensure each bag is filled with the correct amount of rice, beans or sugar, resulting in product quality and customer satisfaction.

Cost savings and increased profitability:

By automating the bag packing process, farmers and distributors in Zambia can significantly reduce labor costs. The use of packing machines requires minimal human intervention, thereby reducing the need for a large workforce. Additionally, the machines improve operational efficiency and optimize resource utilization, leading to cost savings and increased profitability for businesses involved in the rice, beans and sugar industry.

Better hygiene and food safety:

It is important to maintain high standards of hygiene and food safety in the agriculture sector. With manual packing methods, there was a risk of contamination and improper sealing, which could affect the quality and shelf life of the products. Automatic packing machines in zambia have advanced sealing mechanisms and hygienic designs that reduce the risk of contamination. It ensures that rice, beans and sugar reach consumers in a safe and pristine condition, meeting essential food safety standards.

Market Competition and Export Opportunities:

Efficient packaging plays an important role in the competitiveness of agricultural products in both domestic and international markets. By adopting advanced packaging technology, Zambian farmers and distributors can increase the visual appeal and marketability of their rice, beans and sugar. Uniformly packaged bags with accurate labeling and attractive designs are more likely to attract consumer attention and gain a competitive edge. Furthermore, the use of advanced packing machines enables businesses to meet export standards, opening up opportunities for international trade and economic growth.

Conclusion:

The introduction of 50 kg bag packing machines has revolutionized the rice, beans and sugar industry in Zambia. With increased automation, improved accuracy, cost savings, enhanced food safety and market competitiveness, these machines have significantly transformed the packaging process. As Zambia continues to prioritize agricultural development, the adoption of advanced technologies will pave the way for further progress in this sector, benefiting farmers, distributors and consumers alike.

Rice: Rice Packing Machine, Rice Bag Packing Machine, Rice Packaging Equipment, Automatic Rice Packing Machine, Rice Bagging Machine, Rice Filling Machine, Rice Packaging Line

We Sell Manufacturer, Trade, Import, Supply 5kg 10kg 50kg automatic Rice bag packing Zambia

5kg 10kg 50kg automatic Rice bag packing Description

5kg 10kg 50kg automatic Rice bag packing machine/Maize Corn Wheat flour packaging machine/Fish meal Grain weight packing machine

BAGGING MACHINE, Maize Flour Filling

· Model: ASTRA-180

· Application: Bag Filling machine

· Material: Powder, Contact part SS304

· Type: Gross Weighed, Bagging System

· Weighing Capacity:10-50 kg

· Speed: 3-4 Bags/Minute(240

Bags/Hour)

· Accuracy: 0.7% FSD

· Load Cell Based Weighing System

· IP65 Control Panel with

Siemens Accessories

Small -With

Feeding Feeder

Machine mounting

structure included

2 Astra-141- STITCHING CONVEYOR

· Model: Astra/141-

· Material: Bag Stitching

· Conveyor Length: 4000mm

· Type: Belt Conveyor/Slat Chain with Strips

conveyor

· Drive motor: 1 HP Motor with Gear Box,

Worm type (40 ratio)

· Control panel with siemens accessories

· Conveyor Dimensions: L: 4000mm, W:

500mm,

H: Adjustable By Screw (450mm

600mm)

· Portable Stitching Stand

· Construction: MS with Powder C

Standard model Heavy Duty Bag

Closing Machine

Country Info

Zambia, in southern Africa, is a landlocked country of rugged terrain and diverse wildlife, with many parks and safari areas. On its border with Zimbabwe is famed Victoria Falls indigenously called Mosi-oa-Tunya, or “Smoke That Thunders plunging a misty 108m into narrow Batoka Gorge. Spanning the Zambezi River just below the falls is Victoria Falls Bridge, a spectacular viewpoint. ? Google

Other Keywords Related to 5kg 10kg 50kg automatic Rice bag packing

poultry bagging machine

rice bagging machine

cereal bagging machine

rice packaging equipment

50 kg bag packing machine price

rice bag packing machine

rice bag making machine

gunny bag stitching machine price

rice bag sewing machine price

rice bag sealing machine price

rice bag manufacturing machine

50 kg rice packing machine

rice bag packing machine price

automatic rice bag filling machine

25 kg bag filling machine

25 kg bag sealing machine

50kg automatic packing machine

50kg bag packing machine

20kg bagging machine

used 25kg bagging machine

25kg powder packing machine

25 kg bag filling machine

We are India Based Packaging Machine manufacturer company with state of Art Manufacturing unit fully equipped with Most Advanced Research and Development center and specialized manpower, well known for Precision, Fast delivery and prompt customer care support of 24/7. We provide machine to all countries of World. Recent Exports were in Australia, Canada, UK, USA, Nigeria, Uganda, Turkey, Singapore, New Zealand, France, Spain, Italy..

Supper power packaging systems provides cost guarantee with our all products. You will never get such quality and cost anywhere in world.

Our Manufacturing capacity is huge just because we have world class infrastructure and storage unit. We manufacture monthly 15 machines.

We have huge categories of products for packaging machines. Moreover, we can provide you custom solution for all your packaging needs.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

Our R&D team is fully equip with all technologies which help us to create new products every week. This can be identify as our strength.

We have a dedicated team for customer support which is available for 24 hours and 7 days. You can contact us via, Phone, Email, Call or whats-app.

Supper power packaging systems provides cost guarantee with our all products. You will never get such quality and cost anywhere in world.

We have huge categories of products for packaging machines. Moreover, we can provide you custom solution for all your packaging needs.

Our R&D team is fully equip with all technologies which help us to create new products every week. This can be identify as our strength.

Our Manufacturing capacity is huge just because we have world class infrastructure and storage unit. We manufacture monthly 15 machines.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

Find us on youtube

Supper Power Pack Systems Developed by Supper Power Pack Systems & Packing Machine World

Content is protected.