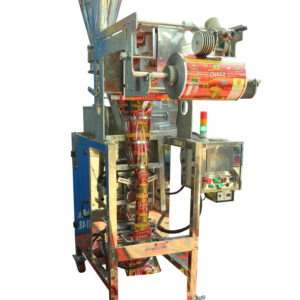

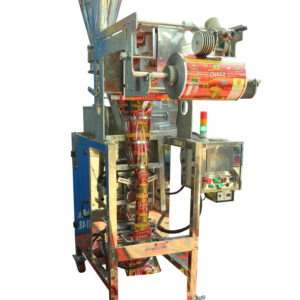

Vertical Form Fill Seal machine to pack Spices Powder

Our offer is as follows.

Pack Type:- Center sealed Pillow Pouch

Film Type :- Heat Sealable Multilayer Laminate.

Filling Rage-500gms To 5000 gms

Accuracy :- +/- 3gm of fill volume

Speed :- 30 to 70 packs per min

VERTICAL FORM FILL SEAL MACHINE HF

Automatic Masala Powder Packing Machine in Zambia

Supper Power Pack Systems offers spice and curry powder packing machines in Zambia, designed to meet the growing demand for high-quality packaging in the food industry. Their machines are engineered for efficiency and precision, ensuring that spices and curry powders are packed with minimal waste and in a hygienic, secure manner. These machines can handle various types of spice powders, providing options for different packaging formats such as sachets, pouches, or bags.

Key features of the spice curry powder packing machines from Super Power Pack Systems typically include:

If you’re interested in acquiring a spice or curry powder packing machine for your business in Zambia, Supper Power Pack Systems can provide tailored solutions to match your production needs. They can also offer after-sales support, installation, and maintenance services to ensure smooth operations.

Convenience and Consumer Appeal:

The spice powder pouch packing machine has also greatly benefited Zambian consumers. The pouches produced by the machine are lightweight, compact and easy to handle, making them convenient for storage and transportation. Precise packaging measurements eliminate the need for manual measuring spoons or cups, simplifying the cooking process for consumers. Additionally, the sealed pouches protect the spice powder from moisture, pests and external contaminants, ensuring that the product remains fresh and unadulterated until it is consumed.

conclusion:

The introduction of the Spice Powder Pouch Packing Machine has brought a new era of efficiency, accuracy and convenience to the packaging industry in Zambia. By automating the packaging process, manufacturers have experienced increased productivity, cost savings and improvements in product quality. On the other hand, consumers get the benefits of convenience and freshness of well-packaged spice powder products. As this innovative technology continues to evolve, it is expected to contribute to the growth and development of Zambia’s food industry, meeting the demands of both the domestic and international markets while maintaining the rich flavor and cultural heritage of Zambian cuisine. Is.

We Sell Manufacturer, Trade, Import, Supply Masala Powder Packing Machine Zambia

Masala Powder Packing Machine Description

Powder Automatic Packing Machine Auger Filler Coffee Milk Powder

Packaging Machine

ASTRA-87- Automatic Vertical Packing Machine For Spices Powder

High Speed machine 10gms to 1000gms

This machine is automatic Vertical from Fill Seal with volumetric servo

Auger Filler machine; With this machine you can pack spice powder 10

grams 25 grams 50 grams can be 100 grams of 200 grams 500 grams and

1000 grams, this is one of the world’s such There is no machine in it or

there is no maintenance mechanical machine. This machine runs from a

computer control system. This is a high speed machine. It will get

program set up. How program settings work I can say, save 10 grams in

program number 1 and save 20 grams in program number 2 save 50

grams in program number 3 and save 100 grams in program number 4, by

doing this, you can add all the products Save the settings in the display

once, select the program number that is to run and start the machine, the

old data on the machine will come This area is very good machine again

and will once more have no product settings we put on a lot of space in

the machine India,

– Vertical Form Fill Seal machine to pack Spices Powder

– Our offer is as follows.

– Pack Type:- Center sealed Pillow Pouch

– Film Type :- Heat Sealable Multilayer Laminate.

– Filling Rage-500gms To 5000 gms

– Accuracy :- +/- 3gm of fill volume

– Speed :- 30 to 70 packs per min

– VERTICAL FORM FILL SEAL MACHINE HF

Pneumatic Type machine with coller.

– Constant heat seal bars for sealing the horizontal seal and double draw for vertical seal.

controlled Induction motor for film draw down by rubbarised belts.

– make PLC with 7 colour touch screen HMI for controls. SCHNEIDER

– Motors for film unwinding and trolley movement.

– PID controllers for temperature control.

– MS sq pipe structure with ceramic painting, with all contact parts in SS 304.

– With one set of forming size parts.

.

A) TECHNICAL SPECIFICATIONS OF VFFS BAGGER MODEL 91+-VFFS

B) PNEUMATIC CYCLINDER AND VALE FESTO MAKE

?? (W/O PULLING BELTS). Servo Motor , LXM 26 Modal- SCHNEIDER

??Operational control of VFFS Bagger thru PLC controller, SCHNEIDER- ..

??Temperature adjustment through PID CONTROLLERS –

??Motorized Film Unwinding Mechanism.

??Built in Print Mark registration Device, PEPPERL+FUCHS,-GERMANY.

??Air removing flaps to remove most of air from pouch.

??Level sensor for No Product No Pouch

??MAX. ROLL WIDTH 550 mm.

, NITROGEN GAS FLUSH,

Servo Volumetric Auger filler powder

Features

? Servo Driven for high efficiency & accuracy. Precise & accurate dosing.

? Integrated with bagger through network. Works in synchronization with

bagger speed.

? Can work with close loop system, if attached with check weigher as an

option.

? Rugged construction ensuring consistent high dosing accuracy.

? All contact parts made out from stainless steel 304.

? Fast & easy cleaning agitator hopper design.

Auger filling 10, gms to 1000gms

Output ; 30 Up 70 Pouches/ Per Mint,

??AIR REQUIREMENT 300 LIT/MIN. AT THE PRESSURE OF 6KG/CM2.

??OPTIONAL ATTACHMENT: BATCH CODING DEVICE, NITROGEN GAS FLUSH,

PERFORATION SYSTEM AND INFEED BUCKET ELEVATOR.

1. The machine requires 5HP, 415V, 50 Hz , 3 Phase, 4 Wire electrical supply and the same is to be

made available through 2.5 sq. mm. 4 core armoured copper

Country Info

Zambia, in southern Africa, is a landlocked country of rugged terrain and diverse wildlife, with many parks and safari areas. On its border with Zimbabwe is famed Victoria Falls indigenously called Mosi-oa-Tunya, or “Smoke That Thunders plunging a misty 108m into narrow Batoka Gorge. Spanning the Zambezi River just below the falls is Victoria Falls Bridge, a spectacular viewpoint. ? Google

Other Keywords Related to Masala Powder Packing Machine

masala powder packing machine

masala packing machine

powder packing machine

masala packing machine price

masala packing

masala pouch packing machine

powder packaging machine

digital control particle filling machine

masala machine fully automatic

detergent powder packing machine

second hand masala packing machine

ch

We are India Based Packaging Machine manufacturer company with state of Art Manufacturing unit fully equipped with Most Advanced Research and Development center and specialized manpower, well known for Precision, Fast delivery and prompt customer care support of 24/7. We provide machine to all countries of World. Recent Exports were in Australia, Canada, UK, USA, Nigeria, Uganda, Turkey, Singapore, New Zealand, France, Spain, Italy..

Supper power packaging systems provides cost guarantee with our all products. You will never get such quality and cost anywhere in world.

Our Manufacturing capacity is huge just because we have world class infrastructure and storage unit. We manufacture monthly 15 machines.

We have huge categories of products for packaging machines. Moreover, we can provide you custom solution for all your packaging needs.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

Our R&D team is fully equip with all technologies which help us to create new products every week. This can be identify as our strength.

We have a dedicated team for customer support which is available for 24 hours and 7 days. You can contact us via, Phone, Email, Call or whats-app.

Supper power packaging systems provides cost guarantee with our all products. You will never get such quality and cost anywhere in world.

We have huge categories of products for packaging machines. Moreover, we can provide you custom solution for all your packaging needs.

Our R&D team is fully equip with all technologies which help us to create new products every week. This can be identify as our strength.

Our Manufacturing capacity is huge just because we have world class infrastructure and storage unit. We manufacture monthly 15 machines.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

Find us on youtube

Supper Power Pack Systems Developed by Supper Power Pack Systems & Packing Machine World

Content is protected.