Features of Automatic Complete carbonated filling machine

Design: Vertical Cylindrical tank with Center Low RPM Stirrer .

The tank shell will be of 2.mm thick S.S. sheets of SS304-

The tank bottom conical will be of 2.5.mm thick S.S. sheets of SS304

The tanks will be supported on S.S three legs provided with S.S. adjustable heavy duty ball feet for level adjustment, the bottom of the tank is conical type and also connected towards outlet for free and complete drainage of Juice.

All SS surfaces will matt polished to 220 grit, ground & smooth.

The Tank will be provided with following accessories

Top cover with two side openable lead Inlet connection with T.C. Connection for Pulp. (1no.)

Inlet connection with T.C. Flavor/Sugar syrup Water. (1no.)

Carbonated beverage filling machine in Malawi

Supper Power Pack Systems, a renowned manufacturer and exporter of advanced packaging machinery based in Jaipur, India, offers a range of high-performance filling machines. One of their standout products is the Carbonated Soft Drink (CSD) Bottle Filling Machine, specifically designed for the efficient and precise bottling of carbonated beverages, including sodas, soft drinks, and sparkling waters.

With an expanding global footprint, Supper Power Pack Systems is a trusted supplier to the beverage industry in Malawi, providing state-of-the-art solutions that ensure high-quality packaging and streamlined production lines for CSD manufacturers.

The CSD Bottle Filling Machine is ideal for:

For Malawi-based beverage manufacturers looking to enhance their CSD production capabilities, Supper Power Pack Systems provides the perfect solution with its Carbonated Soft Drink (CSD) Bottle Filling Machine. Designed for efficiency, reliability, and quality, these machines are ideal for large-scale production lines and are capable of meeting the growing demand for carbonated beverages in the region.

Detail Specification

Sugar syrup preparation tank with low RPM stirrer (2 H.P)

Capacity – 1000Ltr

Function Requirement: Sugar Syrup Preparation tank is used for dissolving sugar in hot water to prepare sugar syrup.

Design: Vertical Cylindrical tank with Center Low RPM Stirrer .

The tank inner shell will be of 2 mm thick S.S. sheets of SS304.

The outer shell will be insulated with 100 mm thick 30 kg/mtr density glass wool/Cerawool and covered with 1.6 mm thick welded SS304 sheets.

The tanks will be supported on S.S three legs provided with S.S. adjustable heavy duty ball feet for level adjustment, the bottom of the tank is conical type type and also connected with Flush Bottom Valve to towards outlet for free and complete drainage of sugar syrup.

Electrically heated with temperature controlling system.

All SS surfaces will matt polished to 220 grit, ground & smooth.

The Tank will be provided with following

Sugar syrup filter press with transfer

pump It has facility to removing initial air from inside through air release valve.

Pressure gauge is provided to check filter chocking level(Pressure)

The stainless steel filter presses body is made to a special modular design that guarantees precisely the right filtration requirement for this application.

Easy open able body it is made out of SS304 quality sheet and provided with specially designed plate & safety valve.

Can use multi use washable filter cloth or use

n through grade filter cloth.

Vertical “Zero hold up design “ to use last drop of sugar syrup ( Crompton/equivalent

make)

40 BPM soft drink plant

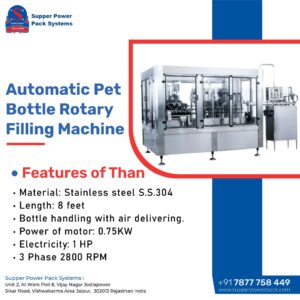

Fully Automatic CSD Rinsing, Filling, Capping Machine 9-9-4 Rotary Based

(Cold Filling process)—-Filling Pressure will be 2 to 4 deg. Temperature.

8 Head Rising, 8 Head Counter pressure Filling and 4 Head Screw capping machine with cap Feeder, VFD etc.

In feed Air Conveyor

Exit Conveyor

Theoretical Output :- up to 40 BPM

INFEED AIR CONVEYOR

The empty bottles are loaded manually onto the in feed air conveyor where air at high pressure from a blower is used for conveying bottles supported at the neck upto the infeed bottle transfer rotor. The air conveyor permits different bottle sizes to run without making any adjustments. Hence there is no wastage of time in conveyor adjustment on the in feed side.

INFEED BOTTLE TRANSFER ROTOR

The bottles are transferred to rinse rotor by the in feed bottle transfer rotor. Bottles are held at the neck during transfer.

The automatic rinse rotor has spring loaded grippers mounted radially which pick up bottles one by one from the infeed transfer rotor. The bottle is inverted against a lever on the rinse valve to start the rinsing operation. Thus we have NO BOTTLE – NO RINSE. Bottles are washed for upto three seconds each, before draining (for removal of residual water) and up righting for transfer to the filling rotor. The rinsing medium is generally product water.

FILLING ROTOR

The internationally accepted and approved VENT PIPE filling principle ensures accurate level filling without spillage. The filling accuracy is +- 5ml. The fill tank level is regulated automatically by a PLC controlled electronic probe which reduces the machine speed in the vent of disrupted input product water supply. The machine speed is them restored to normal once the water supply is replenished.

Technical Specification

Online Disc Filter

C.I.P pipe line For soft drink

S.S 304 25mm C.I.P line Parallelly use same pump and ss304 tank used for C.I.P. S.S 304

C.I.P spray ball used in tank

Interconnecting S.S. Pipes and Fittings —

SS 304 for soft drink

S.S. Pipes and Fittings for the equipment.

The piping will be 25 mm as applicable based on the flow rate requirements. The fittings

will be of TC end standard.

MULTI STAGE Carbonator – 1000Ltr

(Standard) with high pressure pump for carbonation (Lubi Make)

Stainless steel high quality carbonated soft drink carbonation mixer, multi layer S.S plate for more precise carbonation with stainless steel vertical high pressure pump, insulted vessel, zero hold up design, C02 regulation system, high pressure auto and manual

safety valve provided

Standard Quality Glycol based chiller

with

Compressor

( Copland and safety denfoss make) 304 glycol insulated tank

Pre carbonation PHE with Glycol

circulation pump and automation with carbonator

CO2Mani fold –

Carbon dioxide multi cylinder connector with CO2 pressure gage and pressure regulator with header

Application / Uses

Automatic Carbonated soft Drink Packaging line with water bottling machine.

What we do?

We Manufacture , Export , Supply , Trade , Import Carbonated beverage filling machine in Malawi

Call us or fill the form for more information.

What we do ? we Carbonated beverage filling machine in Malawi and supply

Commissioning & After-sales Service

1.We make accurate factory layout design according to customer’s factory size; if the customer needed, we could make workshop design with electricity power, Aircumeresur supply, Plastic Rolles, material storage,packing meterial final storages, worker’s restroom, etc.

2.After delivering machines to client’s factory, we start to apply for the Visa to client’s country immediately; normally the vessel needs 20-60 days to the required port, so we have enough time to get the Visa. While the machines arrives your factory, our engineers are ready to start for the commissioning service.

3.1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production at shortest time.

4.Our engineers have responsibility to train and teach the workers how to operate, clean, maintain and repair all the machines, until the workers could well operate the processing line.

5.It normally costs 5 days for the commissioning service, and we supply 1 year Warranty from the date of completion of commissioning service.

6.The engineer’s round-trip flight tickets, accommodation and daily salary 8000 are on client’s account.

Note-

Supervision charges for Installation & commissioning

Extra as per quoted in our technical offer.

The customer will ensure that the equipment have been placed at site & necessary connections are completed before

the call for commissioning has been made. You will have to provide to & fro, & lodging & boarding during the stay of

our engineer.

If the additional visit is required by the engineering then additional charges would be of Rs. 3500/- per day per person

per man hours

| Albania | Central African Republic | Gaza Strip | Lithuania | Paraguay | Tanzania |

| Algeria | Chad | Georgia | Luxembourg | Peru | Thailand |

| American Samoa | Chile | Germany | Macau | Philippines | The Bahamas |

| Andorra | Christmas Island | Ghana | Macedonia | Pitcairn Islands | The Gambia |

| Angola | Colombia | Gibraltar | Madagascar | Poland | Timor-Leste |

| Anguilla | Comoros | Greece | Malawi | Portugal | Togo |

| Antigua And Barbuda | Congo (Brazzaville) | Greenland | Malaysia | Puerto Rico | Tonga |

| Argentina | Congo (Kinshasa) | Grenada | Maldives | Qatar | Trinidad And Tobago |

| Armenia | Cook Islands | Guadeloupe | Mali | Reunion | Tunisia |

| Aruba | Costa Rica | Guam | Malta | Romania | Turkey |

| Australia | Côte dIvoire | Guatemala | Marshall Islands | Russia | Turkmenistan |

| Austria | Croatia | Guinea | Martinique | Rwanda | Turks And Caicos Islands |

| Azerbaijan | Cuba | Guinea-Bissau | Mauritania | Saint Barthelemy | Tuvalu |

| Bahrain | Curaçao | Guyana | Mauritius | Saint Helena | U.S. Virgin Islands |

| Bangladesh | Cyprus | Haiti | Mayotte | Saint Kitts And Nevis | Uganda |

| Barbados | Czechia | Honduras | Mexico | Saint Lucia | Ukraine |

| Belarus | Denmark | Hong Kong | Moldova | Saint Martin | United Arab Emirates |

| Belgium | Djibouti | Hungary | Monaco | Saint Pierre And Miquelon | United Kingdom |

| Belize | Dominica | Iceland | Mongolia | Saint Vincent And The Grenadines | USA |

| Benin | Dominican Republic | India | Montenegro | Samoa | Uruguay |

| Bermuda | Ecuador | Indonesia | Montserrat | San Marino | Uzbekistan |

| Bhutan | Egypt | Iran | Morocco | Sao Tome And Principe | Vanuatu |

| Bolivia | El Salvador | Iraq | Mozambique | Saudi Arabia | Vatican City |

| Bosnia And Herzegovina | Equatorial Guinea | Ireland | Myanmar | Solomon Islands | Venezuela |

| Botswana | Eritrea | Isle Of Man | Namibia | South Africa | Vietnam |

| Brazil | Estonia | Israel | Nauru | South Georgia And South Sandwich Islands | Wallis And Futuna |

| British Virgin Islands | Ethiopia | Italy | Nepal | South Korea | West Bank |

| Brunei | Falkland Islands (Islas Malvinas) | Jamaica | Netherlands | South Sudan | Yemen |

| Bulgaria | Faroe Islands | Japan | New Caledonia | Spain | Zambia |

| Burkina Faso | Federated States of Micronesia | Jersey | New Zealand | Sri Lanka | Zimbabwe |

| Burundi | Fiji | Jordan | Nicaragua | Sudan | Kyrgyzstan |

| Cabo Verde | Finland | Kazakhstan | Niger | Suriname | Laos |

| Cambodia | France | Kenya | Nigeria | Svalbard | Latvia |

| Cameroon | French Guiana | Kiribati | Niue | Swaziland | Lebanon |

| Canada | French Polynesia | Kosovo | Norfolk Island | Sweden | Lesotho |

| Cayman Islands | Gabon | Kuwait | North Korea | Switzerland | Papua New Guinea |

| Liberia | Liechtenstein | Panama | Northern Mariana Islands | Taiwan | |

| Libya | Oman | Palau | Norway | Tajikistan | |

| carbonated beverage filling machine |

| carbonated drink filling machine |

| soft drink filling machine |

| soda bottling machine |

| soda gas filling machine |

| carbonated soft drink filling machine |

| carbonated filling machine |

| carbonated water filling machine |

| cold drink filling machine |

| fully automatic soda making machine |

| soft drink packaging machine |

| second hand soda filling machine |

| semi automatic soda filling machine |

| automatic soft drink filling machine |

| soda filling and capping machine |

| soft drink can filling machine |

| soft drink canning machine |

| carbonated can filling machine |

| small carbonated drink filling machine |

| carbonated drink bottling machine |

| used carbonated beverage filling machine |

| carbonated beverage bottling equipment |

| soft drink filling machine price |

| soft drink packing machine |

Why Malawi for Carbonated beverage filling machine ?

Malawi, a landlocked country in southeastern Africa, is defined by its topography of highlands split by the Great Rift Valley and enormous Lake Malawi. The lake’s southern end falls within Lake Malawi National Park – sheltering diverse wildlife from colorful fish to baboons – and its clear waters are popular for diving and boating. Peninsular Cape Maclear is known for its beach resorts. ? Google

We are India Based Packaging Machine manufacturer company with state of Art Manufacturing unit fully equipped with Most Advanced Research and Development center and specialized manpower, well known for Precision, Fast delivery and prompt customer care support of 24/7. We provide machine to all countries of World. Recent Exports were in Australia, Canada, UK, USA, Nigeria, Uganda, Turkey, Singapore, New Zealand, France, Spain, Italy..

Supper power packaging systems provides cost guarantee with our all products. You will never get such quality and cost anywhere in world.

Our Manufacturing capacity is huge just because we have world class infrastructure and storage unit. We manufacture monthly 15 machines.

We have huge categories of products for packaging machines. Moreover, we can provide you custom solution for all your packaging needs.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

Our R&D team is fully equip with all technologies which help us to create new products every week. This can be identify as our strength.

We have a dedicated team for customer support which is available for 24 hours and 7 days. You can contact us via, Phone, Email, Call or whats-app.

Supper power packaging systems provides cost guarantee with our all products. You will never get such quality and cost anywhere in world.

We have huge categories of products for packaging machines. Moreover, we can provide you custom solution for all your packaging needs.

Our R&D team is fully equip with all technologies which help us to create new products every week. This can be identify as our strength.

Our Manufacturing capacity is huge just because we have world class infrastructure and storage unit. We manufacture monthly 15 machines.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

Content is protected.