Features of Fully Automatic Real juice Packaging line

2000 Litters Function Requirement: Blending with Flavor, water & pulp for making Juice.

Design: Vertical Cylindrical tank with Center Low RPM Stirrer .

The tank shell will be of 2.mm thick S.S. sheets of SS304-

The tank bottom conical will be of 2.5.mm thick S.S. sheets of SS304

The tanks will be supported on S.S three legs provided with S.S. adjustable heavy duty ball feet for level adjustment, the bottom of the tank is conical type and also connected towards outlet for free and complete drainage of Juice

Juice bottle filling machine in Burundi

Supper Power Pack Systems, a leading packaging machinery manufacturer based in Jaipur, India, specializes in offering high-quality Juice Bottle Filling Machines. These machines are designed for efficient and precise filling of juices, making them ideal for bottling fruit and vegetable juices in the beverage industry. Supper Power Pack Systems has gained recognition for providing durable and reliable packaging solutions, and their expertise extends to markets such as Gitega, Burundi.

These machines are designed for a wide range of juice applications, including:

Supper Power Pack Systems is proud to export their Juice Bottle Filling Machines to Gitega, Burundi, where they have established a strong presence in the local market. With increasing demand for packaged beverages in Burundi, these machines offer a reliable and cost-effective solution for local manufacturers seeking to enhance their production capabilities.

The company’s commitment to quality, excellent customer service, and timely delivery makes it a trusted partner for juice bottling plants in Burundi and beyond. Supper Power Pack Systems understands the unique needs of the African market and offers machines that are not only efficient but also built to withstand the local operational conditions.

For businesses in Gitega, Burundi, looking to improve their juice production and packaging processes, Supper Power Pack Systems offers the perfect solution with their state-of-the-art Juice Bottle Filling Machines. With advanced technology, cost-effective pricing, and dependable after-sales service, Supper Power Pack Systems has earned its reputation as the leading supplier and exporter of juice bottling machines in Burundi.

For further information, inquiries, or quotes, reach out to Supper Power Pack Systems today to get your Juice Bottle Filling Machine for enhanced production efficiency and quality.

Detail Specification

Pulp receiving/Pectin/Gum Mixing tank

500 ltr Jacketed with high speed Stirrer ( electric heated )Function Requirement: pulp receiving and dumping from tin can

/Drum

Design: Vertical Cylindrical tank

The tank shell will be of 2 mm thick S.S

Fully Automatic Real juice and synthetic

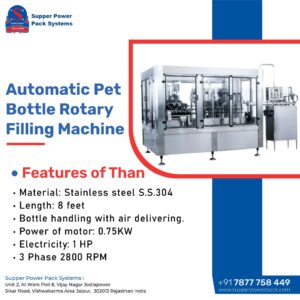

juice Rinsing, Filling, Capping Machine 8- 8-4 Rotary Based (Hot Felling )

(Hot Filling process)

8 Head Rising, 8 Head GRAVITY Filling and 4 Head Screw capping machine with cap Feeder, VFD etc.

In feed Air Conveyor

Exit Conveyor

Theoretical Output :- up to 40 BPM

Cooling tunnel use for bottle cooling

C.I.P pipe line For juice plant

S.S 304 25mm C.I.P line Parallelly use same pump and ss304 tank used for C.I.P. S.S 304

C.I.P spray ball used in tank

Interconnecting S.S. Pipes and Fittings —

SS 304 for juice plant

S.S. Pipes and Fittings for the equipment.

The piping will be 25 mm as applicable based on the flow rate requirements. The fittings

will be of TC end standard.

Online ink jet coding machine

Online Digital Video Jet 3 Line Ink jet coding/ Printing machine

Online Steam shrink tunnel with steam

generator

mtr long S steam tunnel Steam generator

Steam generator mounted on S.S pipes structure and covered with SS sheet

18 KW heater are used

System is design for 2.5 kg saturated steam production constantly

With high pressure cut off & low pressure start system.

“No water” heater will not

Automatic tank level control system with high pressure transfer pump.

Steam generator is connected with SS flexible pipes.(Crompton Pump Used)

Steam tunnel having small steam storage facility & with control and drain valve

Semi auto bulk shrink wrapping machine

with Standard based compressor (2 HP) With Semi automatic functions of bottle arranging, shrink packing, sealing and cutting shrinking, cooling and shaping, etc

Using advanced constant temperature heat sealing technology with clear and secure seal

With programmable timer semi automatic program control with stable and reliable performance.

All the transfer system is controlled by frequency converter /DC drive with stable and smooth transfer

Speed

Output 3 to 5 Packets/Min.

that has an equal heat distribution with beautiful and secure shrinkage effect

heat insulation treatment with good insulating properly, quick temperature rise and energy saving

Unique thermal passage with centrifugal thermal air circulation system

sheets of SS304-

The tanks will be supported on S.S four legs provided with S.S. adjustable heavy duty ball feet for level adjustment, the bottom of the tank is dish end type and also connected with valve to outlet for free and complete drainage of sugar syrup.

All SS surfaces will matt polished to 220 grit, ground & smooth.

The Tank will be provided with following accessories

No foam inlet with T.C. Connection. ( 1 no.) Pulp outlet with T.C. Connection. (1no.)

Three Nos S.S. adjustable heavy duty ball feet for level adjustment.

S.S.C.I.P. (Cleaning) spray balls ending on outside with a small hole nozzle with T.C. connection One No.

Side Drain with Valve

ONLINE PESTURISER FOR JUICE

( 1000 ltr /hr) (PLATE HEAT EXCHANGER)

PHE type with SS 316 plates with glue less food grade EPDM gaskets,

Frame & pressure plate M.S with SS304 cladding. Temp will be 30/35-90/85-72 Deg

heating by hot water, and cooling room temperature juice or cooling tower water in feed .

Capacity 500lt/Hr

Return Juice PHE For Homogenizer

Cooling tower Cooling tower for cooling

tunnel with circulation pump

Boiler Wood Fired Boiler For Pasteurizing

and homogenizing process of juice

Chimney and Pressure reducing System

Chimney

Pressure reducing System

HIGH PRESSURE HOMOGENIZER FOR

JUICE (1000 ltr /hr)Two stage homogenizer design.

Maximum Pressure : 200 Bar

Operating Pressure : 175 Bar No. of Plunger :3

MOC of Plunger: Special Alloy with hard chrome plated

Homogenizer Speed : 275 SPM (Suitable for Continuous duty)

Electric Drive Motor : 5/ HP 3 phase 960 RPM, 410 Volts (Kirloskar / Bharat Bijilee) M 0 C of all fluid Contact Surface : AISI 304 (S.S.)

The Body : The body of the Homogenizer casing is made out of C. Iron.

M 0 C of Homogenizer Valve & Seat: Import Stellite (Germany)

Type of Suction & dis. Valve: Ball type suitable for Fruit Juice

M 0 C of suction & dis. valve : AISI 304 with Satellite.

Temperature holding system Holding tube

is designed for continuous holding of the product for 20/30

sec, at the pasteurization temperature.

Holding tube is of tubular design

made of SS 316 seamless tube with suitable

number of bend

Application / Uses

Automatic Real juice Mango POMEGRANATE FRUIT MOSAMBI

PINEAPPLE

LITCHI FRUIT

ORANGE

GRAPES Packaging line

What we do?

We Manufacture , Export , Supply , Trade , Import Juice bottle filling machine in Burundi

Call us or fill the form for more information.

What we do ? we Juice bottle filling machine in Burundi and supply

Commissioning & After-sales Service

1.We make accurate factory layout design according to customer’s factory size; if the customer needed, we could make workshop design with electricity power, Aircumeresur supply, Plastic Rolles, material storage,packing meterial final storages, worker’s restroom, etc.

2.After delivering machines to client’s factory, we start to apply for the Visa to client’s country immediately; normally the vessel needs 20-60 days to the required port, so we have enough time to get the Visa. While the machines arrives your factory, our engineers are ready to start for the commissioning service.

3.1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production at shortest time.

4.Our engineers have responsibility to train and teach the workers how to operate, clean, maintain and repair all the machines, until the workers could well operate the processing line.

5.It normally costs 5 days for the commissioning service, and we supply 1 year Warranty from the date of completion of commissioning service.

6.The engineer’s round-trip flight tickets, accommodation and daily salary 8000 are on client’s account.

Note-

Supervision charges for Installation & commissioning

Extra as per quoted in our technical offer.

The customer will ensure that the equipment have been placed at site & necessary connections are completed before

the call for commissioning has been made. You will have to provide to & fro, & lodging & boarding during the stay of

our engineer.

If the additional visit is required by the engineering then additional charges would be of Rs. 3500/- per day per person

per man hours

| Albania | Central African Republic | Gaza Strip | Lithuania | Paraguay | Tanzania |

| Algeria | Chad | Georgia | Luxembourg | Peru | Thailand |

| American Samoa | Chile | Germany | Macau | Philippines | The Bahamas |

| Andorra | Christmas Island | Ghana | Macedonia | Pitcairn Islands | The Gambia |

| Angola | Colombia | Gibraltar | Madagascar | Poland | Timor-Leste |

| Anguilla | Comoros | Greece | Malawi | Portugal | Togo |

| Antigua And Barbuda | Congo (Brazzaville) | Greenland | Malaysia | Puerto Rico | Tonga |

| Argentina | Congo (Kinshasa) | Grenada | Maldives | Qatar | Trinidad And Tobago |

| Armenia | Cook Islands | Guadeloupe | Mali | Reunion | Tunisia |

| Aruba | Costa Rica | Guam | Malta | Romania | Turkey |

| Australia | Côte dIvoire | Guatemala | Marshall Islands | Russia | Turkmenistan |

| Austria | Croatia | Guinea | Martinique | Rwanda | Turks And Caicos Islands |

| Azerbaijan | Cuba | Guinea-Bissau | Mauritania | Saint Barthelemy | Tuvalu |

| Bahrain | Curaçao | Guyana | Mauritius | Saint Helena | U.S. Virgin Islands |

| Bangladesh | Cyprus | Haiti | Mayotte | Saint Kitts And Nevis | Uganda |

| Barbados | Czechia | Honduras | Mexico | Saint Lucia | Ukraine |

| Belarus | Denmark | Hong Kong | Moldova | Saint Martin | United Arab Emirates |

| Belgium | Djibouti | Hungary | Monaco | Saint Pierre And Miquelon | United Kingdom |

| Belize | Dominica | Iceland | Mongolia | Saint Vincent And The Grenadines | USA |

| Benin | Dominican Republic | India | Montenegro | Samoa | Uruguay |

| Bermuda | Ecuador | Indonesia | Montserrat | San Marino | Uzbekistan |

| Bhutan | Egypt | Iran | Morocco | Sao Tome And Principe | Vanuatu |

| Bolivia | El Salvador | Iraq | Mozambique | Saudi Arabia | Vatican City |

| Bosnia And Herzegovina | Equatorial Guinea | Ireland | Myanmar | Solomon Islands | Venezuela |

| Botswana | Eritrea | Isle Of Man | Namibia | South Africa | Vietnam |

| Brazil | Estonia | Israel | Nauru | South Georgia And South Sandwich Islands | Wallis And Futuna |

| British Virgin Islands | Ethiopia | Italy | Nepal | South Korea | West Bank |

| Brunei | Falkland Islands (Islas Malvinas) | Jamaica | Netherlands | South Sudan | Yemen |

| Bulgaria | Faroe Islands | Japan | New Caledonia | Spain | Zambia |

| Burkina Faso | Federated States of Micronesia | Jersey | New Zealand | Sri Lanka | Zimbabwe |

| Burundi | Fiji | Jordan | Nicaragua | Sudan | Kyrgyzstan |

| Cabo Verde | Finland | Kazakhstan | Niger | Suriname | Laos |

| Cambodia | France | Kenya | Nigeria | Svalbard | Latvia |

| Cameroon | French Guiana | Kiribati | Niue | Swaziland | Lebanon |

| Canada | French Polynesia | Kosovo | Norfolk Island | Sweden | Lesotho |

| Cayman Islands | Gabon | Kuwait | North Korea | Switzerland | Papua New Guinea |

| Liberia | Liechtenstein | Panama | Northern Mariana Islands | Taiwan | |

| Libya | Oman | Palau | Norway | Tajikistan | |

| juice bottle filling machine |

| juice bottling machine |

| bottle shape pouch filling machine |

| juice bottling equipment |

| small juice filling machine |

| litchi juice filling machine |

| juice bottling machine for sale |

| hot juice filling machine |

| bottle shape juice pouch packing machine |

| juice bottle packing machine |

| juice bottle sealing machine |

| litchi bottle sealing machine |

| fruit juice bottling machine |

| litchi juice packing machine |

| bottle juice filling machine |

| small scale juice bottling equipment |

| pet bottle juice filling machine |

| juice filling and capping machine |

| glass bottle juice filling machine |

| juice filling equipment |

| juice bottle packaging machine |

Why Burundi for Juice bottle filling machine ?

Burundi, officially the Republic of Burundi, is a landlocked country in the Great Rift Valley at the junction between the African Great Lakes region and East Africa. Wikipedia

Burundi, a picturesque country in East Africa, is known for its lush landscapes and vibrant agricultural sector. As the nation continues to develop, its food and beverage industry is also experiencing significant growth. Among the essential equipment driving this growth are juice bottle filling machines. These machines play a crucial role in ensuring that locally produced juices are efficiently bottled and ready for market consumption. This article delves into the world of juice bottle filling machines in Burundi, exploring their benefits, technological advancements, and impact on the local beverage industry.

Burundi’s agricultural sector is a cornerstone of its economy, with a substantial portion of the population engaged in farming. The country’s fertile soil and favorable climate conditions support the cultivation of a variety of fruits, which are ideal for juice production. As the demand for locally produced juices grows, so does the need for efficient bottling solutions.

The beverage industry in Burundi has seen a surge in both domestic consumption and export opportunities. Consumers are increasingly seeking high-quality, locally sourced beverages, prompting producers to invest in advanced bottling technologies. Juice bottle filling machines have emerged as indispensable assets in this regard, enabling producers to meet the growing demand while maintaining product quality and safety.

Juice bottle filling machines are vital for several reasons. First and foremost, they ensure that juices are bottled quickly and efficiently, minimizing the risk of contamination. These machines are designed to handle various types of juices, including those with pulp or other particulates, ensuring a consistent fill level and preserving the quality of the product.

Moreover, juice bottle filling machines enhance production capacity, allowing manufacturers to scale their operations to meet increasing market demands. They also help in maintaining hygiene standards, which is crucial in the food and beverage industry. By automating the bottling process, these machines reduce the risk of human error and ensure that each bottle is filled accurately and sealed properly.

The juice bottle filling machines available today are a far cry from their earlier counterparts. Technological advancements have revolutionized these machines, making them more efficient, reliable, and user-friendly. Here are some key features of modern juice bottle filling machines:

The adoption of juice bottle filling machines in Burundi offers numerous benefits to local producers and the broader economy. Here are some of the key advantages:

To illustrate the transformative impact of juice bottle filling machines in Burundi, let’s consider a hypothetical case study of a local juice producer, “Burundi Fresh Juices.”

Burundi Fresh Juices is a mid-sized company that sources fruits from local farmers to produce a range of natural juices. The company has been in operation for five years and has seen steady growth in demand for its products. However, the manual bottling process used by the company has become a bottleneck, limiting its ability to scale up production and maintain consistent product quality.

Recognizing the need for modernization, Burundi Fresh Juices decided to invest in an advanced juice bottle filling machine. The company chose a model with automated cleaning, filling, and sealing capabilities, capable of handling various bottle sizes and juice types.

While the benefits of juice bottle filling machines are clear, their adoption is not without challenges. Here are some common challenges and potential solutions:

The future of juice bottle filling machines in Burundi looks promising. As the beverage industry continues to grow, the demand for advanced bottling solutions will likely increase. Innovations in technology, such as the integration of IoT (Internet of Things) and AI (Artificial Intelligence), are expected to further enhance the efficiency and capabilities of these machines.

Producers who embrace these advancements will be well-positioned to capitalize on the expanding market opportunities, both locally and internationally. Additionally, the focus on sustainability and energy efficiency will drive the development of eco-friendly filling solutions, aligning with global trends towards sustainable manufacturing practices.

Juice bottle filling machines are revolutionizing the beverage industry in Burundi. These advanced machines offer numerous benefits, including increased production efficiency, enhanced product quality, and cost savings. By investing in modern bottling technologies, local producers can meet growing market demands, compete effectively, and contribute to the country’s economic development.

As Burundi’s beverage industry continues to evolve, the adoption of juice bottle filling machines will play a crucial role in shaping its future. With a focus on innovation, quality, and sustainability, Burundi is poised to become a significant player in the global juice market, delivering high-quality, locally produced beverages to consumers around the world.

Cities We Supply :

We are India Based Packaging Machine manufacturer company with state of Art Manufacturing unit fully equipped with Most Advanced Research and Development center and specialized manpower, well known for Precision, Fast delivery and prompt customer care support of 24/7. We provide machine to all countries of World. Recent Exports were in Australia, Canada, UK, USA, Nigeria, Uganda, Turkey, Singapore, New Zealand, France, Spain, Italy..

Supper power packaging systems provides cost guarantee with our all products. You will never get such quality and cost anywhere in world.

Our Manufacturing capacity is huge just because we have world class infrastructure and storage unit. We manufacture monthly 15 machines.

We have huge categories of products for packaging machines. Moreover, we can provide you custom solution for all your packaging needs.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

Our R&D team is fully equip with all technologies which help us to create new products every week. This can be identify as our strength.

We have a dedicated team for customer support which is available for 24 hours and 7 days. You can contact us via, Phone, Email, Call or whats-app.

Supper power packaging systems provides cost guarantee with our all products. You will never get such quality and cost anywhere in world.

We have huge categories of products for packaging machines. Moreover, we can provide you custom solution for all your packaging needs.

Our R&D team is fully equip with all technologies which help us to create new products every week. This can be identify as our strength.

Our Manufacturing capacity is huge just because we have world class infrastructure and storage unit. We manufacture monthly 15 machines.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

Find us on youtube

Supper Power Pack Systems Developed by Supper Power Pack Systems & Packing Machine World

Content is protected.