SUPPER POWER PACK SYSTEMS (Based in Jaipur, India)

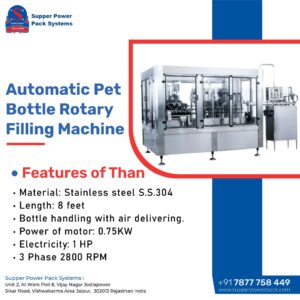

Supper Power Pack Systems, a leading packaging machine manufacturer and exporter based in Jaipur, India, supplies 500ml and 1-liter mineral water bottle filling machines to Uganda, catering to the increasing demand for safe and efficient water packaging in the region.

These machines are engineered for high accuracy, speed, and hygiene in filling, ensuring bottled water producers in Uganda can scale operations while maintaining quality.

✅ Automatic Rinsing, Filling, and Capping in a single machine.

✅ SS304/SS316 Construction for hygiene and corrosion resistance.

✅ PLC Controlled with touch screen for easy operation and monitoring.

✅ High-Speed Filling: Suitable for 500ml and 1L bottles without extensive changeover time.

✅ Precise Filling: Gravity or pressure filling technology for exact volume control.

✅ Low Maintenance & Energy Efficient design.

✅ Suitable for PET, HDPE, and glass bottles.

Packaged mineral water bottling plants.

Small and medium-scale bottled water production.

NGOs, hotels, and water projects seeking in-house bottling for consistent quality.

| Machine Capacity | Output (BPH) | Price Range (FOB India) |

|---|---|---|

| 500ml – 1L (Semi-Auto) | 300-600 BPH | USD 7,500 – 17,000 |

| 500ml – 1L (Automatic 3-in-1) | 1000-2000 BPH | USD 15,500 – 28,500 |

| 500ml – 1L (High-Speed Auto) | 3000-4000 BPH | USD 34,000 – 62,000 |

Note: Prices vary based on:

✅ Proven Export Track Record in East Africa.

✅ Spare Parts & Remote Support availability.

✅ Training & Installation Guidance provided upon request.

✅ Machines designed for tropical climates with durable construction.

✅ Competitive pricing with uncompromised quality.

Remote troubleshooting via WhatsApp, Zoom, or video calls.

Easy availability of consumables and spares.

Operator training manuals and operational videos.

Local logistic support assistance for customs clearance.

1️⃣ Share your required output (BPH) and budget range.

2️⃣ Indicate if you need a turnkey project with water treatment, labeling, and packaging.

3️⃣ Supper Power Pack Systems will prepare a detailed quotation with machine specifications, payment terms, and delivery timeline.

Supper Power Pack Systems specializes in liquid filling, pouch packing, and shrink-wrapping machines, exporting to over 35 countries, including Uganda, Zambia, Kenya, and Tanzania. The company’s mission is to empower small and medium enterprises with affordable, reliable packaging solutions for water bottling and beverage industries.

Rotary machines streamline the bottling process by integrating washing, filling, and capping into a single, continuous operation. This automation significantly increases throughput, reducing the time and labor required to process each bottle.

Maintaining hygiene is crucial in the beverage and pharmaceutical industries. Rotary bottle washing, filling, and capping machines ensure bottles are thoroughly cleaned, filled in a sterile environment, and securely sealed, reducing the risk of contamination.

Automated rotary machines provide precise control over the filling volume and capping torque, ensuring consistent product quality and reducing wastage due to overfilling or underfilling.

These machines are designed to handle various bottle sizes and shapes, making them suitable for different products, including water, juices, soft drinks, and pharmaceuticals.

The integrated design of rotary machines allows for seamless transitions between washing, filling, and capping stages, enhancing overall efficiency and reducing space requirements.

Rotary machines are capable of processing thousands of bottles per hour, making them ideal for high-volume production lines.

Modern rotary machines are equipped with advanced control systems, including programmable logic controllers (PLCs) and human-machine interfaces (HMIs), for precise operation and easy monitoring.

Manufacturers offer customizable configurations to meet the specific needs of different industries and products. This includes options for various bottle sizes, filling methods, and capping techniques.

Built with high-quality materials, rotary machines are designed to withstand the rigors of continuous operation, ensuring durability and long-term reliability.

Krones AG is a global leader in the manufacturing of packaging and bottling equipment. Known for their cutting-edge technology and reliable machinery, Krones offers a range of rotary bottle washing, filling, and capping machines suitable for various industries.

Sidel is another prominent player in the packaging machinery industry. With a focus on innovation and sustainability, Sidel’s rotary machines are designed to deliver high performance while minimizing environmental impact.

GEA Group specializes in process technology and equipment, including rotary bottling machines. Their solutions are renowned for their precision, efficiency, and versatility, catering to diverse packaging needs.

Tech-Long is a leading manufacturer of beverage packaging machinery, offering advanced rotary bottle washing, filling, and capping machines. Their equipment is designed for high-speed production lines and ensures optimal hygiene and product quality.

The price of rotary bottle washing, filling, and capping machines can vary based on several factors, including:

In Uganda, the price of rotary bottle washing, filling, and capping machines can range from $50,000 to $300,000 or more, depending on the factors mentioned above. Entry-level models suitable for small to medium-sized businesses may fall at the lower end of the range, while high-capacity, fully automated machines with advanced features are priced at the higher end.

By automating the bottling process, these machines significantly boost production efficiency, allowing businesses to meet higher demand without compromising on quality.

Although the initial investment may be substantial, the long-term cost savings from reduced labor, minimized product wastage, and improved operational efficiency can be substantial.

The precision and consistency offered by rotary machines ensure that every bottle is filled and sealed to the same high standard, enhancing overall product quality and customer satisfaction.

Automated rotary machines help businesses comply with stringent hygiene and safety standards, essential for the beverage and pharmaceutical industries.

As businesses grow, rotary machines can be upgraded or expanded to accommodate increased production volumes, providing scalability and flexibility.

Evaluate your production requirements, including the type of product, bottle sizes, and production volumes, to determine the specifications you need in a machine.

Look beyond the initial purchase price and consider the total cost of ownership, including maintenance, energy consumption, and potential downtime.

Research and compare different manufacturers, considering factors such as reputation, after-sales support, and the availability of spare parts.

Whenever possible, request demonstrations of the machines and seek references from other businesses that have used the equipment to gain insights into performance and reliability.

Choose a machine that can accommodate your future growth and changing production needs, ensuring long-term value from your investment.

Investing in a rotary bottle washing, filling, and capping machine can transform your production line, offering unparalleled efficiency, hygiene, and precision. For businesses in Uganda, these machines represent a valuable investment, enhancing product quality, meeting regulatory standards, and driving growth. By understanding the key features, pricing factors, and benefits, you can make an informed decision and choose the right machine to meet your specific needs. As the packaging industry continues to evolve, staying ahead with advanced technology and reliable equipment will ensure your business remains competitive and successful in the market.

Cities We supply :

We are India Based Packaging Machine manufacturer company with state of Art Manufacturing unit fully equipped with Most Advanced Research and Development center and specialized manpower, well known for Precision, Fast delivery and prompt customer care support of 24/7. We provide machine to all countries of World. Recent Exports were in Australia, Canada, UK, USA, Nigeria, Uganda, Turkey, Singapore, New Zealand, France, Spain, Italy..

Supper power packaging systems provides cost guarantee with our all products. You will never get such quality and cost anywhere in world.

Our Manufacturing capacity is huge just because we have world class infrastructure and storage unit. We manufacture monthly 15 machines.

We have huge categories of products for packaging machines. Moreover, we can provide you custom solution for all your packaging needs.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

Our R&D team is fully equip with all technologies which help us to create new products every week. This can be identify as our strength.

We have a dedicated team for customer support which is available for 24 hours and 7 days. You can contact us via, Phone, Email, Call or whats-app.

Supper power packaging systems provides cost guarantee with our all products. You will never get such quality and cost anywhere in world.

We have huge categories of products for packaging machines. Moreover, we can provide you custom solution for all your packaging needs.

Our R&D team is fully equip with all technologies which help us to create new products every week. This can be identify as our strength.

Our Manufacturing capacity is huge just because we have world class infrastructure and storage unit. We manufacture monthly 15 machines.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

Content is protected.