· Picked cartons will be placed inside the each pockets of conveyor.

· This machine consist cam operated pocket conveyor system with sliding mechanism.

· Tablets pusher mechanism is placed parallel to Pouch carrying conveyor which pushes the Pouch inside the individual cartons.

· After Pouch insertion each cartons passes through cartons flap tuckin mechanism which is palced parallel on both side of the conveyor.

· Hot melt Gluing unit mounted after side flap folding assembly.

· In tuckin mechanism first side flaps will gets folded through mechanical fingers.

· At next station bottom flaps will gets folded through mechanically Guides.

· After flap folding end product will be ejected to output conveyor.

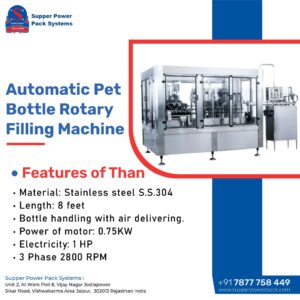

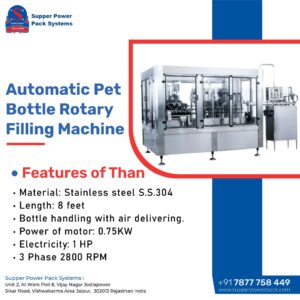

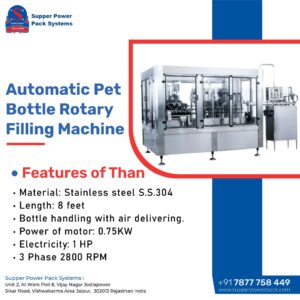

Supplier & Exporter – SUPPER POWER PACK SYSTEMS (Based in Jaipur, India)

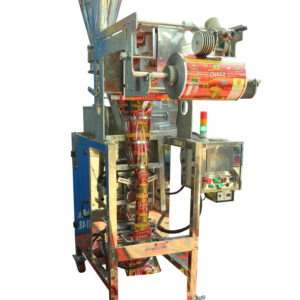

Supper Power Pack Systems, a leading packaging machinery manufacturer from Jaipur, India, supplies high-performance Biscuit Vertical Packaging Machines to Uganda and other African markets. These machines are specially engineered to meet the growing demand for efficient, hygienic, and reliable packaging solutions in the food industry.

Vertical Form-Fill-Seal (VFFS) Technology – Ensures automatic pouch forming, filling, and sealing.

High-Speed Operation – Capable of packing biscuits in pillow packs, center-seal pouches, or gusseted pouches.

Precise Weighing & Filling – Integrated with a volumetric cup filler or multi-head weigher for accuracy.

Hygienic Design – Built with food-grade stainless steel to maintain product quality and freshness.

Flexible Packaging Options – Compatible with different pouch sizes, printed or laminated films.

User-Friendly Control Panel – Touch-screen PLC interface for easy operation and adjustments.

Energy Efficient & Durable – Low maintenance and designed for long-term industrial use.

Biscuits & Cookies Packaging

Bakery Products (Rusk, Wafers, Crackers)

Snack Foods (Chips, Namkeen, Confectionery)

Semi-Automatic Biscuit Packaging Machine: USD 6,000 – 9,000

Fully Automatic Vertical Biscuit Packaging Machine: USD 10,000 – 18,000

(Final price depends on capacity, automation level, and customization required.)

Over 25+ years of expertise in packaging machinery.

Machines exported globally, including Uganda and other African nations.

Custom-built solutions to match production needs.

FOB India sea port shipping, ensuring safe and timely delivery.

Comprehensive after-sales support and spare parts availability.

For biscuit manufacturers in Uganda, investing in a Vertical Packaging Machine from Supper Power Pack Systems ensures higher production efficiency, consistent packaging quality, and reduced operational costs. With FOB pricing from India, businesses can easily set up or expand their biscuit packaging operations with world-class technology.

We Sell Manufacturer, Trade, Import, Supply Biscuit Packing machine Uganda

Biscuit Packing machine Description

Automatic Horizontal Corn Flake Cartoning Machine Food Pouch Carton Box Packing Machine

Description and operations

Model- Astra-40

Automatic Cartoning machine

· Cartooning need to be loaded onto the hopper on loading platform is provided to minimal the feeding frequency.

· Individual cartons will be pick place onto the pocket conveyor which is parallel to the Pouch pocket conveyor.

· Cartons will be pick and place through individual heads through suction cups with the help of vaccum.

· Picked cartons will be placed inside the each pockets of conveyor.

· This machine consist cam operated pocket conveyor system with sliding mechanism.

· Tablets pusher mechanism is placed parallel to Pouch carrying conveyor which pushes the Pouch inside the individual cartons.

· After Pouch insertion each cartons passes through cartons flap tuckin mechanism which is palced parallel on both side of the conveyor.

· Hot melt Gluing unit mounted after side flap folding assembly.

· In tuckin mechanism first side flaps will gets folded through mechanical fingers.

· At next station bottom flaps will gets folded through mechanically Guides.

· After flap folding end product will be ejected to output conveyor.

Interlocks

· No Pouch no carton.

· No carton no Pouch push(ejected in bin).

· Mechanical jam drives slip through mechanical clutch mechanism.

· No cartons at hopper machine stops.

· Low air pressure machine off.

· Emergency stop cartooning machine Off.

Output

40-60 CPM

Power Transmission

Simplex chain /gears /Timing belt

Hopper Belt

Fabric Endless Belt (depends cartons)

Conveyor motor

Hindustan motors 3phase induction motor

Bearings/liner guides

SKF/ Nachi / Hiwin

Carton Holding conveyor chain

Diamond

Simplex chain

Rollon / Diamond

Machine main Gear box

Bonfigloli Inline Helical Gear box

Pneumatic components/cylinders

Festo Make

Cylinder type

Double acting

Contact parts

S.S304

Non-contact parts

ALU/ MS/plastic /S.S/D2

Parts finishing

Hard croming/ENP/Powder coating Buffing/Anodising/silver plating

Safety Guards

Available for moving parts

Bottom cover

available

PLC

Schneider

HMI

Schneider

Servo Motor

Schneider

VFD

Schneider

Electrical Contactor Relay

Schneider / Siemens

Country Info

Uganda is a landlocked country in East Africa whose diverse landscape encompasses the snow-capped Rwenzori Mountains and immense Lake Victoria. Its abundant wildlife includes chimpanzees as well as rare birds. Remote Bwindi Impenetrable National Park is a renowned mountain gorilla sanctuary. Murchison Falls National Park in the northwest is known for its 43m-tall waterfall and wildlife such as hippos. ? Google

Other Keywords Related to Biscuit Packing machine

multi pack biscuit packing machine

manual biscuit packing machine

automatic biscuit packing machine

bakery biscuit packing machine

small biscuit packing machine

parle g biscuit packing machine

khosla biscuit packing machine

biscuit wrapping machine

automatic biscuit packing machine

cookie packaging machine

biscuit pouch packing machine

cookies filling machine

cookie packaging equipment

individual cookie packaging machine

milk packing machine

packing machine for food products

We are India Based Packaging Machine manufacturer company with state of Art Manufacturing unit fully equipped with Most Advanced Research and Development center and specialized manpower, well known for Precision, Fast delivery and prompt customer care support of 24/7. We provide machine to all countries of World. Recent Exports were in Australia, Canada, UK, USA, Nigeria, Uganda, Turkey, Singapore, New Zealand, France, Spain, Italy..

Supper power packaging systems provides cost guarantee with our all products. You will never get such quality and cost anywhere in world.

Our Manufacturing capacity is huge just because we have world class infrastructure and storage unit. We manufacture monthly 15 machines.

We have huge categories of products for packaging machines. Moreover, we can provide you custom solution for all your packaging needs.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

Our R&D team is fully equip with all technologies which help us to create new products every week. This can be identify as our strength.

We have a dedicated team for customer support which is available for 24 hours and 7 days. You can contact us via, Phone, Email, Call or whats-app.

Supper power packaging systems provides cost guarantee with our all products. You will never get such quality and cost anywhere in world.

We have huge categories of products for packaging machines. Moreover, we can provide you custom solution for all your packaging needs.

Our R&D team is fully equip with all technologies which help us to create new products every week. This can be identify as our strength.

Our Manufacturing capacity is huge just because we have world class infrastructure and storage unit. We manufacture monthly 15 machines.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

Find us on youtube

Supper Power Pack Systems Developed by Supper Power Pack Systems & Packing Machine World

Content is protected.