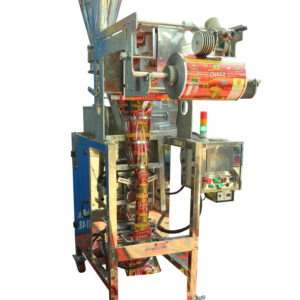

Pneumatic Type machine with coller.

Constant heat seal bars for sealing the horizontal seal and double draw for vertical seal. controlled Induction motor for film draw down by rubbarised belts.

make PLC with 7 colour touch screen HMI for controls.

Motors for film unwinding and trolley movement.

PID controllers for temperature control.

MS sq pipe structure with ceramic painting, with all contact parts in SS 304.

With one set of forming size parts

vegetable weighing and packing machine in Ghana

Weighing and Packing Machine Supplier in Ghana: Supper Power Pack Systems

Introduction

The demand for efficient packaging solutions is growing rapidly in Ghana, particularly in sectors like food processing, agriculture, and manufacturing. Packaging is essential for product protection, transportation, and storage, making the right packaging equipment crucial for businesses. One such essential piece of equipment is the weighing and packing machine, which combines precision weighing with reliable packaging to streamline production. Super Power Pack Systems is a leading supplier of these machines, offering high-quality equipment that meets the unique needs of Ghanaian businesses.

About Supper Power Pack Systems

Super Power Pack Systems has established itself as a reliable name in the packaging machinery industry, providing a range of solutions designed to meet diverse packaging requirements. Known for its durable, efficient, and user-friendly machines, Super Power Pack Systems offers equipment that stands up to the rigors of production environments while delivering consistent, accurate results. The company specializes in machines that cater to various industries, including food, pharmaceuticals, and agriculture, ensuring businesses get tailored solutions.

Types of Weighing and Packing Machines Offered

Benefits of Choosing Super Power Pack Systems

Why Choose Supper Power Pack Systems as Your Supplier?

As a reliable supplier, Super Power Pack Systems has a deep understanding of the packaging industry and offers a wide selection of weighing and packing machines that cater to businesses of all sizes. Here are some reasons why Super Power Pack Systems stands out:

Conclusion

In Ghana’s competitive business landscape, efficiency and precision in packaging can make a significant difference in profitability and customer satisfaction. Supper Power Pack Systems’ weighing and packing machines provide the accuracy, speed, and reliability needed to stay ahead in today’s market. From automatic and semi-automatic options to customized solutions for specific industries, Super Power Pack Systems offers equipment that fits the unique requirements of Ghanaian businesses.

conclusion:

The packaging industry in Ghana can greatly benefit from the adoption of 10-head weigher packing machines. These machines provide increased productivity, increased accuracy, versatility, reduced labor requirements, improved cleanliness and overall cost-effectiveness. By taking advantage of the benefits of this advanced technology, Ghanaian packaging companies can streamline their operations, increase efficiency and meet the growing demands of the market while ensuring high quality packaged products

We Sell Manufacturer, Trade, Import, Supply Full automatic multihead weigher 10 head weigher packing machine for potato chips blister with Nitrogen flushing Ghana

Full automatic multihead weigher 10 head weigher packing machine for potato chips blister with Nitrogen flushing Description

Full automatic multihead weigher 10 head weigher packing machine for potato chips blister with Nitrogen flushing

we understand you require a Vertical Form Fill Seal machine to pack Namkeens,

. Our offer is as follows.

Pack Type:- Center sealed Pillow Pouch

Film Type :- Heat Sealable Multilayer Laminate.

Filling Rage-200gms To 900gms

Filler Type :- Weighed

Accuracy :- +/- 1gm of fill volume

Speed :- 15 to 40 packs per min

VERTICAL FORM FILL SEAL MACHINE HF

– Pneumatic Type machine with coller.

– Constant heat seal bars for sealing the horizontal seal and double draw for vertical seal. controlled Induction motor for film draw down by rubbarised belts.

– make PLC with 7 colour touch screen HMI for controls.

– Motors for film unwinding and trolley movement.

– PID controllers for temperature control.

– MS sq pipe structure with ceramic painting, with all contact parts in SS 304.

– With one set of forming size parts.

.

A) TECHNICAL SPECIFICATIONS OF VFFS BAGGER MODEL 80-VFFS

ü (W/O PULLING BELTS). Servo Motor , LXM 26 Modal-

ü Operational control of VFFS Bagger thru PLC M200 controller, SCHNEIDER- ..

ü Temperature adjustment through PID CONTROLLERS –

ü Motorized Film Unwinding Mechanism.

ü Built in Print Mark registration Device, PEPPERL+FUCHS,-GERMANY.

ü Air removing flaps to remove most of air from pouch.

ü Level sensor for No Product No Pouch

ü MAX. ROLL WIDTH 500 mm.

Multi 10 Head [Make-

10 Head Weigher Specification

Volume

1.6L

Weight Range

20g – 1000g

Accuracy

0.5 – 1.5g

Max Speed

70 wpm

Programs

99

Control

7.4 inch touch screen

Construction

Stainless Steel

Program Recovery Function

yes

IP65 Waterproof Standard

yes

Multiple Languages

yes

Drive system

Stepper Motor

Options

10 Head Multihead are our entry level machines. With a maximum speed of 70 weights per minute, these machines offer great advantages over Manual Weighing or Linear Weighing. With an accuracy of 0.5 – 1.5g per weight you will see savings immediately on product giveaway and weighing efficiency.

These machines are ideal for weighing dried fruit, nuts, seeds, crisps, vegetables, nuts and bolts etc. Multi easy-flowing with high accuracy;

· IP65waterproof and dustproof design, which is easy t clean and maintain; Multilanguage control panel, Spanish, Korean, German, French and Arabic,

Power Requirements

220V/1000W/50/60HZ/10A

Packing Dimension(mm)

1482(L)x1080(W)x1116(H)

Working Platform ,

Size 2400MM*2400MM,*2000MM,

Cover For Checker Sheet, Aluminum,

Bucket elevator for food conveying: Note Hight 3200MM Drop

bucket elevator for food conveying ( Supper Power Pack )

Droping Hight 2600mm

This machine is mainly used for granular bulk materials ascension conveying. Such chips, peanut, sweets, dried fruits, vegetables, frozen food, vegatables, chemical and other granular or block items.

* Hoist hopper is made of food-grade polypropylene (PP), with artistic looking, not easy to deform, resist heat and cold.

* Simple maintenance, disassembling easyly and convenient cleaning.

We are India Based Packaging Machine manufacturer company with state of Art Manufacturing unit fully equipped with Most Advanced Research and Development center and specialized manpower, well known for Precision, Fast delivery and prompt customer care support of 24/7. We provide machine to all countries of World. Recent Exports were in Australia, Canada, UK, USA, Nigeria, Uganda, Turkey, Singapore, New Zealand, France, Spain, Italy..

Supper power packaging systems provides cost guarantee with our all products. You will never get such quality and cost anywhere in world.

Our Manufacturing capacity is huge just because we have world class infrastructure and storage unit. We manufacture monthly 15 machines.

We have huge categories of products for packaging machines. Moreover, we can provide you custom solution for all your packaging needs.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

Our R&D team is fully equip with all technologies which help us to create new products every week. This can be identify as our strength.

We have a dedicated team for customer support which is available for 24 hours and 7 days. You can contact us via, Phone, Email, Call or whats-app.

Supper power packaging systems provides cost guarantee with our all products. You will never get such quality and cost anywhere in world.

We have huge categories of products for packaging machines. Moreover, we can provide you custom solution for all your packaging needs.

Our R&D team is fully equip with all technologies which help us to create new products every week. This can be identify as our strength.

Our Manufacturing capacity is huge just because we have world class infrastructure and storage unit. We manufacture monthly 15 machines.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

Content is protected.