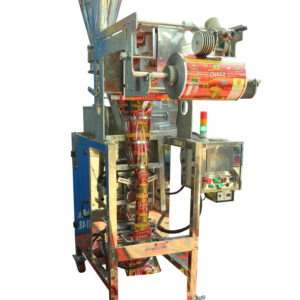

* Electronic Panel Started Steel 1.6mm Fabrication

* Back door , left door , Machine Top Plate Cover Stared Steel

* Front plate cover Mild Steel Powder coated ,

* Filling capacity ; 70 Gms to180Gms

Dish 500mm , cup for pp

Output ; Speed 100Gm – 30 to 35 Pouch Per Mint

Type of seal ; Center seal

Packing material ; any heat sealable laminated material like

,

Depend on product flow ability and bulk density )

Heating systems; hot bar induction , controlled

Through PID Control ;

Electricity Required ; 420v , 3ph , 50hz

Supplier & Exporter – SUPPER POWER PACK SYSTEMS (Based in Jaipur, India)

Supper Power Pack Systems, a leading packaging machine manufacturer based in Jaipur, India, is a trusted name globally for supplying reliable and high-performance detergent powder packing machines. The company proudly exports its advanced machinery to countries including New Zealand, meeting the evolving demands of the detergent and chemical packaging industry.

Multi-Weight Range Capability

Specifically designed to pack detergent powder in 80g, 200g, 300g, and 500g pouches efficiently and accurately.

Automatic Form Fill Seal (FFS) Technology

Ensures smooth operation with automatic filling, sealing, and cutting – ideal for medium to large-scale production.

High-Speed & Accurate Dosing System

Incorporates volumetric or auger-based fillers for precision dosing, ensuring minimal product waste.

User-Friendly PLC Control Panel

Digital controls allow easy operation, quick changeovers, and error diagnostics.

Rugged Stainless Steel Construction

Designed for durability and hygiene compliance, especially critical in detergent and chemical industries.

Customizable Pouch Styles

Supports center seal, three-side seal, or four-side seal pouch formats as per customer requirements.

Consistent Product Quality: Precision in weight and sealing ensures uniform packaging.

Labor Cost Reduction: Full automation decreases dependence on manual labor.

Compliance with Global Standards: Machines are built with CE/ISO-certified components.

Remote Technical Support: Backed by prompt assistance from Supper Power Pack Systems’ experienced team.

Detergent Powder

Washing Powder

Cleaning Agents

Powdered Chemicals

These machines are perfect for FMCG companies, detergent manufacturers, and contract packaging firms in New Zealand looking for reliable and efficient powder packaging solutions.

Over 25 years of experience in packaging machinery

Exported to 30+ countries including New Zealand, Australia, UAE, and African nations

Custom-engineered solutions for local market needs

Competitive pricing with top-tier machine quality

ASTRA-+56 series of machinery are manufactured especially to suit the budget of budding entrepreneur in small scale and mid-scale industries ,

ASTRA-56 are economy models having many features that all high-tech and expensive machinery has , MICRO PROSH logic controller ) makes it smart and intelligent with electronic brain ,

Its performance is outstanding it is user friendly , seals pouches wrinkles free with intact sealing ,

Its is robust and operates making low noise level,

It consumes less power and optimum in efficiency , reducing packaging costs your products,

Astra 57- IS REAL GENIE WORKING MIRACULOUSLY , UNTIRING , EFFICIENTLY AND FAITHFULLY TO HIS MASTERES COMMAND ,,,,

PACKAGING PRODUCT ; DETERGENT , MAX ROLL WIDTH 100 TO 350 MM,

MATERIAL OF CONSTRUCTION IS FROM SATEDARD STEEL304, AND ALL

CONTACT PARTS ARE FROM SS AND

SS , mirror Baffin

Note: Actual output will depends on film quality & properties. reserve the right to prove above offered outputs on suitable film at their works. Buyer to provide their film rolls in sufficient quantity to check its working at above speeds of machine. The set performance, however, is subject to the following factors:

1. Product properties and behavior

2. Constant product infield & bulk density

3. Film material and properties

4. Proper operation & Maintenance of the packaging machine

* Electronic Panel Started Steel 1.6mm Fabrication

* Back door , left door , Machine Top Plate Cover Stared Steel

* Front plate cover Mild Steel Powder coated ,

* Filling capacity ; 70 Gms to180Gms

Dish 500mm , cup for pp

Output ; Speed 100Gm – 30 to 35 Pouch Per Mint

Type of seal ; Center seal

Packing material ; any heat sealable laminated material like

,

Depend on product flow ability and bulk density )

Heating systems; hot bar induction , controlled

Through PID Control ;

Electricity Required ; 420v , 3ph , 50hz

üTemperature adjustment through PID CONTROLLERS Delta .

PLC Controlled Micro Process ,

TECH PENAL 7 INCH COLURE

Roll holding ; 15 kg

Reel core diameter ; 70 to 76

Machine weight ; 250 Kg Ap.

Type of seal ; center seal

ü Built in Print Mark registration Device, PEPPERL+FUCHS,-GERMANY

Penumatices Festo & SMC, And India ) BASED Sealing.

VIBRATOR FEEDER WITH SENSOR AUTOMACUT SYSTEMS

ü AIR REQUIREMENT 300 LIT/MIN. AT THE PRESSURE OF 6KG/CM2.

Compressed air required AIR REQUIREMENT 300 LIT/MIN. AT THE PRESSURE OF 6KG/CM2.

Country Info

New Zealand is an island country in the southwestern Pacific Ocean. It consists of two main landmassesthe North Island and the South Island and over 700 smaller islands. It is the sixth-largest island country by area, covering 268,021 square kilometres. Wikipedia

Other Keywords Related to Automatic salt and washing powder packing machine

detergent powder packing machine

soap packing machine

liquid detergent filling machine

detergent filling machine

soap paper wrapping machine

soap pouch packing machine

detergent cake packing machine price

soap powder packing machine]

Detergent Soap Packing Machine price

liquid detergent packing machine

semi automatic soap wrapping machine

detergent soap packing machine

detergent cake packing machine price

soap powder packing machine

handmade soap packaging machine

sabun packing machine price

liquid detergent packing machine

washing powder packing machine price

detergent powder filling packing machine

automatic detergent powder packing machine

liquid soap packaging machine

detergent powder packing machine price

fully automatic detergent powder packing machine

We are India Based Packaging Machine manufacturer company with state of Art Manufacturing unit fully equipped with Most Advanced Research and Development center and specialized manpower, well known for Precision, Fast delivery and prompt customer care support of 24/7. We provide machine to all countries of World. Recent Exports were in Australia, Canada, UK, USA, Nigeria, Uganda, Turkey, Singapore, New Zealand, France, Spain, Italy..

Supper power packaging systems provides cost guarantee with our all products. You will never get such quality and cost anywhere in world.

Our Manufacturing capacity is huge just because we have world class infrastructure and storage unit. We manufacture monthly 15 machines.

We have huge categories of products for packaging machines. Moreover, we can provide you custom solution for all your packaging needs.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

Our R&D team is fully equip with all technologies which help us to create new products every week. This can be identify as our strength.

We have a dedicated team for customer support which is available for 24 hours and 7 days. You can contact us via, Phone, Email, Call or whats-app.

Supper power packaging systems provides cost guarantee with our all products. You will never get such quality and cost anywhere in world.

We have huge categories of products for packaging machines. Moreover, we can provide you custom solution for all your packaging needs.

Our R&D team is fully equip with all technologies which help us to create new products every week. This can be identify as our strength.

Our Manufacturing capacity is huge just because we have world class infrastructure and storage unit. We manufacture monthly 15 machines.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

We have deployed specialized manpower with more than 10 years of experience in the packaging machine manufacturers. This has made us prominent.

Content is protected.